- Products

- Catalogs

- News & Trends

- Exhibitions

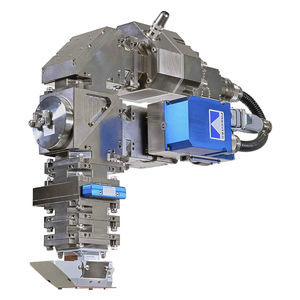

Laser welding head YC52

Add to favorites

Compare this product

Characteristics

- Technique

- laser

Description

In the field of laser cladding, our welding optics with powder nozzle allow you a wide range of applications. Almost pore-free layers with a long service life can be produced completely independent of direction. Typical areas of application are the generation of corrosion and wear protection layers, repairs, and the generation of 3D structures.

The YC52 processing head developed for additive manufacturing offers the same flexibility for your machine concept as the modular processing optics YW30/YW52.

Advantages

• Flexible for many applications in additive manufacturing

Variable track widths and different concepts of powder feeding allow a flexible adaptation to your task.

The following are available for selection:

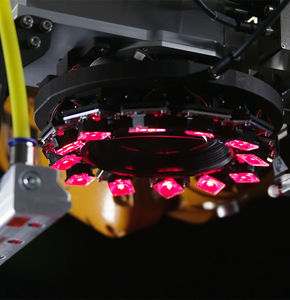

- Coaxial annular gap nozzle to generate a small powder focus and thus a high powder efficiency.

- A multijet coaxial nozzle with four separate powder feeds ideal for 3D applications.

- A lateral nozzle for lateral powder feed with perfect inert gas coverage to produce particularly smooth surfaces.

The fields of application of powder cladding are found in the research sector but also in industrial use. You can process a wide range of materials such as basic alloys of nickel, cobalt, iron or stainless steels, and titanium alloys as well as powder containing tungsten carbide.

Catalogs

No catalogs are available for this product.

See all of PRECITEC OPTRONIK‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.