- Products

- Catalogs

- News & Trends

- Exhibitions

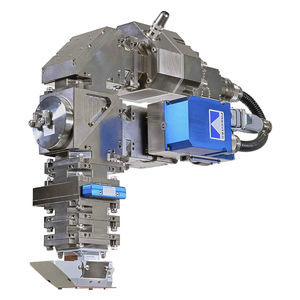

Laser welding head

Add to favorites

Compare this product

Characteristics

- Technique

- laser

Description

High-quality laser welding of copper and aluminum is essential for e-mobility applications. Despite the challenges posed by these reflective and thermally conductive materials, achieving precise welding results is crucial for optimal conductivity and stable circuits.

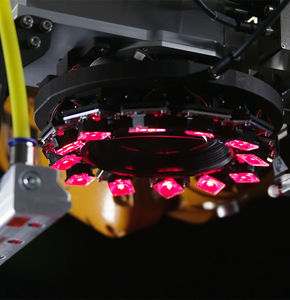

In collaboration with Cailabs, we offer an innovative beam shaping solution that enhances laser interaction with these materials. The use of beam shaping technology splits the laser power into a point and a ring, ensuring that the laser power is distributed evenly. Due to lower thermal load, seams are more homogeneous and the number of spatters is also demonstrably reduced.

Advantages

• Creating a central spot with a surrounding ring

The central spot with surrounding ring result in more homogeneous seams and fewer spatter in laser welding of copper and aluminum

• Fully integrated optical components

With its fully integrated optical components, the flexible laser beam solution is easy to implement and maintenance-free.

• Flexible module for camera integration

the flexible module allows the integration of a camera for teaching and tracking processes

Technical data

• Energy ratio: first set of optics configuration: 80 %(dot) / 20 % (ring) - second set of optics configuration: 70 %(dot) / 30 % (ring)

• Dot diameter: 125 µm

• Ring diameter: 500 µm

• Ring thickness: 125 µm

• Laser max power: 8 kW

Catalogs

No catalogs are available for this product.

See all of PRECITEC OPTRONIK‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.