- Products

- Catalogs

- News & Trends

- Exhibitions

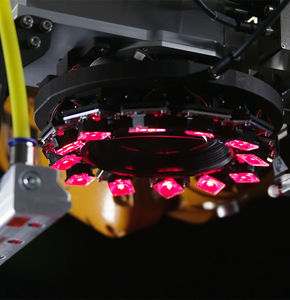

Laser power monitoring system Precitec IDMlaser weldingfor process controlmeasurement

Add to favorites

Compare this product

Characteristics

- Type

- laser power

- Applications

- measurement, for process control, laser welding

- Other characteristics

- online

Description

Monitoring and control of welding depth during laser welding

Advantages

• Online measurement of welding depth

The Precitec IDM measures welding depth coaxially during the laser welding process. Measurement data is always recorded directly from the lowest point of the keyhole based on OCT technology - even at very high welding speeds. The Precitec IDM offers you continuous quality monitoring during the entire laser welding process. Costly and time consuming cross section analyses or destructive tests can be reduced to a minimum.

• 100% documentation, transparency, and traceability

The measuring data recorded during the welding process are used for 100% quality control. By setting upper and lower limits, an immediate warning can be sent to the system control or the machine operator if the values are exceeded. Production errors are detected immediately and can be corrected in time. The data storage in combination with the component ID enables consistent traceability - even years later. This means that the collection, evaluation, and documentation of the data including proof of quality is at your disposal - a comprehensive determination.

• Automated control of welding depth

In addition to the pure measurement, the Precitec IDM offers the possibility to automatically control welding depth. For this purpose, permanently determined actual values are compared with the target values and the welding depth is controlled in real time by adjusting the laser power. In this way, a reliable and reproducible welded joint can be guaranteed, even with demanding and safety-relevant components. The package is rounded off with a user-friendly and intuitive software solution.

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRECITEC OPTRONIK‘s catalogsRelated Searches

- Visible camera system

- Industrial camera system

- Full-color camera system

- Vision processing camera

- Compact imager

- Gigabit Ethernet camera

- High-speed camera system

- Inspection camera system

- Measurement monitoring device

- Real-time monitoring device

- Environmental monitoring device

- Process monitoring device

- Online monitoring device

- Automatic monitoring device

- Power monitoring device

- Optical sensor

- Linear camera

- Monitoring system for the automotive industry

- Compact optical sensor

- Battery monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.