- Metrology - Laboratory

- Inspection and Monitoring

- Process monitoring system

- PRECITEC OPTRONIK

- Products

- Catalogs

- News & Trends

- Exhibitions

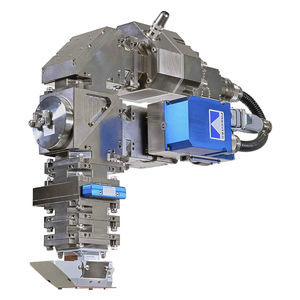

Process monitoring system WeldMaster 4.0laser weldingfieldbusfor the automotive industry

Add to favorites

Compare this product

Characteristics

- Applications

- process, laser welding, fieldbus

- Domain

- for the automotive industry

- Other characteristics

- real-time, automatic, online, position and tracking system

Description

A highly accurate tracking of the joining position, intelligent beam guidance and forming as well as online quality control - the WeldMaster 4.0 offers you all this for your automated welding process. This allows you to implement a complete solution in just one welding station, which is designed for the modern requirements of everyday industrial use.

Advantages

• Automation of your process

The WeldMaster tracking system measures essential geometric variables in the immediate vicinity of the welding position, from which the component position, joining position, and gap are calculated. The information is processed by the system control, and controls beam guidance and forming by means of linear axis and galvanometer scanner. Even for components with tolerances, you get stable welding processes and consistent quality at all times, and independent of material and seam geometry.

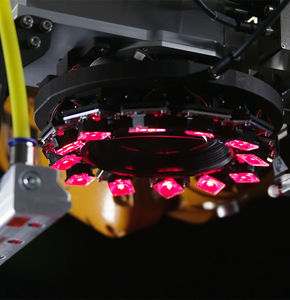

• Quality control in real time

In the immediate aftermath of the laser welding process, the geometric quality control of the joining seam is performed in real time. The Inspect system of the WeldMaster 4.0 eliminates the need for an additional quality station in the flow production. You can measure and evaluate many types of defects such as pores, holes, gaps, notches, and weld formations such as convection, seam width, or the general seam geometry for a wide range of seam shapes.

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRECITEC OPTRONIK‘s catalogsRelated Searches

- Visible camera system

- Industrial camera system

- Full-color camera system

- Vision processing camera

- Compact imager

- Gigabit Ethernet camera

- High-speed camera system

- Inspection camera system

- Measurement monitoring device

- Real-time monitoring device

- Environmental monitoring device

- Process monitoring device

- Online monitoring device

- Automatic monitoring device

- Power monitoring device

- Optical sensor

- Linear camera

- Monitoring system for the automotive industry

- Compact optical sensor

- Battery monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.