- Metrology - Laboratory

- Optical Component

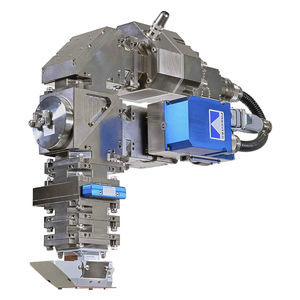

- Welding laser scanner head

- PRECITEC OPTRONIK

- Products

- Catalogs

- News & Trends

- Exhibitions

Welding laser scanner head ScanMaster high-precision

Add to favorites

Compare this product

Characteristics

- Applications

- for welding

- Options

- high-precision

Description

Efficient and highly productive scanner welding

Today, scanner welding enables highly accurate and economical remote processing in series production. With the help of mirrors, the laser beam is positioned within a processing field without having to move the focusing optics or the workpiece. This makes machining highly dynamic, economical and thus efficient.

Scanner optics for remote processing not only enable precise positioning and stable processes

The ScanMaster offers an attractive solution for scanner welding. It combines high-precision distance measurement to the workpiece, auto-focus, component position detection with high-resolution image processing and process monitoring. The ScanMaster has a modular design for this purpose - all performance features can be customised to individual requirements.

Strength, electrical conductivity and tightness are important criteria in the field of e-mobility. Precise, accurate and reproducible production is the focus when contacting power electronics or battery cells.

Advantages

• Stable process with component recognition and autofocus

The fast and precise detection of the component position is essential for optimised machining time. Both the position in the X and Y axis as well as the working distance are fundamental components to execute the process highly dynamically and reproducibly. The focus position can be corrected in real time in the entire process field.

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRECITEC OPTRONIK‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.