- Industrial machines and equipment

- Welding and Assembly

- Arc welding machine

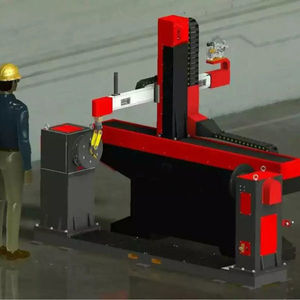

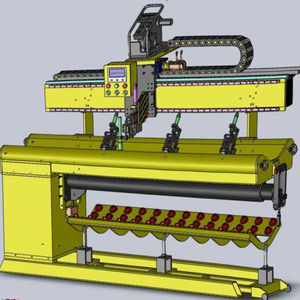

- Prima CNC Machinery

Robotic welding machine TKB1400MIGTIGMAG

Add to favorites

Compare this product

Characteristics

- Technique

- MIG, TIG, MAG, arc

- Operational mode

- robotic

- Other characteristics

- precision

Description

MIG TIG MAG automatic welding 6 Axis welding robot metal welding robot 6 axis

Payload - 6kg

Max Working Radius - 1441.5mm

DOF - 6axis

Body Weight - 160kg

Reducer Brand - Italy RRRobotica

Motor Brand - Italy RRRobotica

Drive Brand - Italy RRRobotica

Rated Power - 2.5kw

Max Speed - J1 - 149°/s

J2 - 149°/s

J3 - 149°/s

J4 - 229°/s

J5 - 180°/s

J6 - 270°/s

Max Operation Area - J1 - ±170°

J2 - 153°~-92°

J3 - 80°~-100°

J4 - ±140°

J5 - ±120°

J6 - ±360°

protective specification - 43

Position Repeat Accuracy - ±0.06mm

controller - TRC3C-B06

Working Temperature - 0~45°

TURIN Welding Robot Features:

Features

Flexible installation method:

TKB1400 Robotic arm span is 1441.5mm 6kg Payload. It can be installed on the ground or upside down flexibly

Excellent price / performance ratio

Product structure design rigorous, the key components are from first-class suppliers, superior product performance. Superior acceleration and deceleration performance, help to shorten the working time, improve production efficiency.

High-end configuration:

The robot’s core components are all imported brands (reducer: 1/2/3 axis, Japan’s Nabtesco; 4/5/6 axis Japan’s new treasure. Servo Drive: South Korea LS. Drive Motor: 1/2/3 Axis, South Korea LS; 4/5/6 axis, Japan Tamagawa), and the use of the most advanced EtherCAT bus technology, with high speed, high precision, good stability, long hours 24 hours continuous operation.

Easy to operate and programming:

Through the intuitive and friendly teaching pendant, robotics and arc welding process can be easily programmed and maintained. The teach pendant uses a popular PC graphical interface, no matter whether the robot is controlled or the specific process equipment

Catalogs

No catalogs are available for this product.

See all of Prima CNC Machinery‘s catalogsRelated Searches

- Industrial press

- Welding system

- Forming press

- Hydraulic press

- Automatic welding system

- Laser welding system

- Electric press

- Metal welding system

- Vertical press

- Precision welding system

- Arc welding system

- Punching press

- Pneumatic press

- Cutting press

- Stamping press

- Process press

- Manual welding system

- Frame press

- Standalone welding system

- Bending press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.