- Industrial machines and equipment

- Welding and Assembly

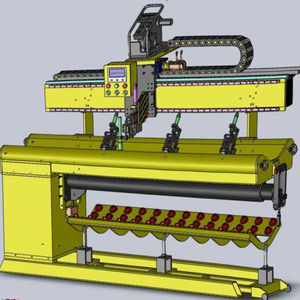

- Arc welding machine

- Prima CNC Machinery

MIG welding machine PM1700TIGarcrobotic

Add to favorites

Compare this product

Characteristics

- Technique

- MIG, TIG, arc

- Operational mode

- robotic

- Other characteristics

- CNC, pneumatic, precision

- Output frequency

50 Hz

Description

TIG or MIG 4 axis welding robot PM1700 with Panasonic Source

Features:

The system also controls the four servo axes at the same time movement; 2. Arc starting arc time precise control; 3. Welding start position can be precisely controlled; 4. According to the product of any programming; 5. Weld uniform beautiful fully.

The whole module uses a walking mechanism:

1, linear guide + ball screw (Taiwan TBI),

2, electrical components (Schneider of France),

3, double valve solenoid valve (Taiwan Yadeke pneumatic hose (Japan), Yuan Long),

4, pneumatic components (Taiwan Yadeke),

5, cylinder (Taiwan Yadeke),

6, servo reducer (Taiwan East).

7, PLC (Korean LG),

8, intelligent man-machine interface touch screen (Wuxi xinje) .

Four-axis welding host description:

four-axis CNC welding host with X, Y, Z-axis linear motion and R-axis rotation movement, to achieve the welding of the linear line or curve movement and welding gun and workpiece welding angle adjustment. Thus completing the welding of various types of welding. X, Y, Z axis movement system using AC servo motor drive, ball screw drive, guide rail, to achieve the precise control of walking, R-axis AC servo motor drive, precision planetary reducer after the drive. Can accurately control the welding gun and the workpiece welding angle adjustment requirements, with X, Y, Z axis to achieve the completion of the welding process.

Four-axis motion control system features:

1.4 axis freedom degree space trajectory motion (straight line, arc, spiral curve). · Teaching track parameters, easy to operate, and support the teaching of graphics preview function,

Catalogs

No catalogs are available for this product.

See all of Prima CNC Machinery‘s catalogsRelated Searches

- Industrial press

- Welding system

- Forming press

- Hydraulic press

- Automatic welding system

- Laser welding system

- Electric press

- Metal welding system

- Vertical press

- Precision welding system

- Arc welding system

- Punching press

- Pneumatic press

- Cutting press

- Stamping press

- Process press

- Manual welding system

- Frame press

- Standalone welding system

- Bending press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.