Dynamic mixer GDLin-linesolid/liquidpowder

Add to favorites

Compare this product

Characteristics

- Technology

- dynamic

- Batch/continuous

- in-line

- Product type

- solid/liquid, powder

- Configuration

- vertical

- Other characteristics

- automatic

- Applications

- for the food industry

- Engine power

4 kW

(5.44 hp)

Description

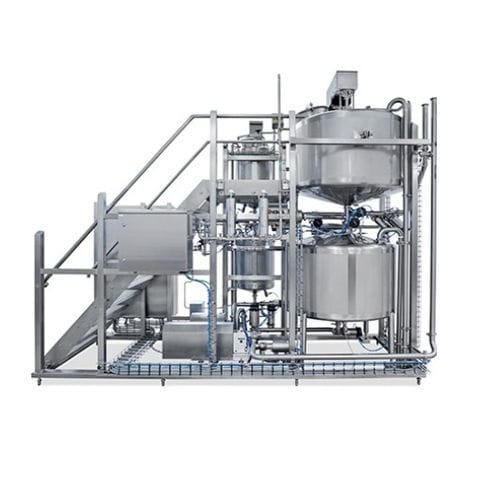

RUNNING INLINE WITH THE FILLING MACHINE

When producing white cheese fermented not by culture but by the acidifying agent known as GDL (Glucono – Delta – Lactone) powder - it is necessary to mix the powder into the cheese milk prior to filling the product.

Primodan has extensive experience in producing GDL mixers for this application, which run inline with the filling machine regardless of whether it is a Tetra Pak carton/brick machine, a SIG combibloc machine or a Primodan cup or canister filling plant.

In our system, we are able to not only mix in GDL powder but also to mix in salt in the same unit, thereby removing the need for pre-salting tanks.The units are produced as semi-automatic or fully automatic depending on the customer´s preference.

Both types are fully CIP cleanable from the customers CIP plant. As an additional feature Primodan offers in-line flavor mixing units, which can be connected to the GDL mixer for mixing in flavor inline before the filling machine

Specifications and options

Technical

Capacity-range: 1,000-5,000 kg/hour

Feedlines: The unit can supply up to 3 filling lines with individual rennet dosing lines

Pneumatic requirement: minimum 6 bar

Electrical consumption: App. 4 kW

Materials: Stainless steel

CE certificate / EU norm

Catalogs

GDL MIXER

4 Pages

WHITE CHEESE PLANT

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.