- Metrology - Laboratory

- Analytical Instrumentation

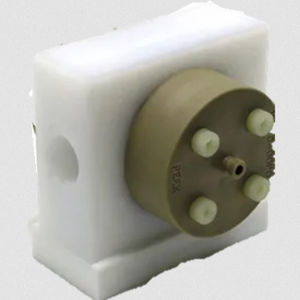

- Turbidity probe

- Process Insights

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Turbidity probe GUIDED WAVE™ fiber opticprocesspolymer

Add to favorites

Compare this product

Characteristics

- Measured value

- turbidity

- Technology

- fiber optic

- Domain

- process, polymer

- Other characteristics

- stainless steel, ANSI, intrinsically safe

Description

Our GUIDED WAVE™ Turbidity Process Probe is designed to withstand corrosive processes. The body of the probe is built from 316L stainless steel. The probe’s sapphire optical windows are sealed to the probe body with polymer O-rings chosen to be compatible with your process. On request, the Turbidity Probe can be supplied welded to an ANSI or DIN process flange. Like our other process probes, 24 inches or longer, it is also compatible with our probe extractor.

Our GUIDED WAVE Turbidity Process Probe with an additional third port can be used for Haze or Turbidity (NTU) measurements with our ClearView® db process photometer. The turbidity measurement detects solids breakthrough in your process while simultaneously measuring the transmission. The 20mm pathlength is appropriate, for example, when monitoring Saybolt color. One of the primary advantages of UV-Vis and NIR process spectroscopy is the utilization of intrinsically safe fiber optic cables to remotely locate the analyzer relative to your process. Inline probes eliminate costly and problematic fast loops and sample systems.

Turbidity Probe Features

Corrosion resistant construction

Rugged design

O-ring process seals

Sealed against ambient moisture infiltration

High optical throughput for low noise spectroscopy

Collimated beam for accurate absorbance measurements

Vibration resistant design

Haze or turbidity measurement is made by a 90° back scatter method. This function requires a third optical fiber to return the scattered light to the analyzer.

Operating Range and Configurations

The operating range of the Turbidity Probe will be determined primarily by the choice of O-ring material.

Catalogs

Related Searches

- LAR Process Analysers gas analyzer

- LAR Process Analysers concentration analyzer

- LAR Process Analysers monitoring analyzer

- LAR Process Analysers liquids analyzer

- LAR Process Analysers automatic analyzer

- LAR Process Analysers benchtop analyzer

- LAR Process Analysers solids analyzer

- Spectrometer

- LAR Process Analysers process analyzer

- Portable analyser

- LAR Process Analysers continuous analyzer

- LAR Process Analysers integration analyzer

- LAR Process Analysers water analyzer

- LAR Process Analysers real-time analyzer

- LAR Process Analysers oxygen analyzer

- LAR Process Analysers compact analyzer

- LAR Process Analysers laboratory analyzer

- LAR Process Analysers infrared analyzer

- LAR Process Analysers calibration analyzer

- LAR Process Analysers in-line analyzer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.