- Metrology - Laboratory

- Analytical Instrumentation

- Process flow cell

- Process Insights

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

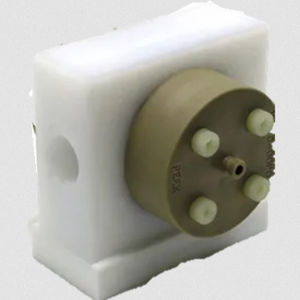

Process flow cell GUIDED WAVE™

Add to favorites

Compare this product

Characteristics

- Other characteristics

- process

Description

Our GUIDED WAVE™ High Safety Flow Cell (HSFC) was engineered for applications involving extremely hazardous materials. When processes involve extremely toxic or hazardous materials such as hydrofluoric acid, phosgene, isocyanates, etc., safety is paramount. Uncontrolled or undetected leaks cannot be tolerated. Our GUIDED WAVE High Safety Flow Cell (HSFC) was designed with leak prevention and early detection in mind. Built into a Class 300 flange, using welded construction, the HSFC uses double O-ring sealed sapphire windows. A weep or “tattletale” port connects to the space between the O-rings and when coupled to a sensor, can indicate O-rings in need of replacement. The GUIDED WAVE High Safety Flow Cell (HSFC) is available in a variety of alloys and O-ring materials selected to be compatible with your process.

High Safety Process Flow Cell Features

Suitable for extremely hazardous sample streams

Built into a ½” class 300 flange

Patented Double O-ring sealed design

Safety sniffer port provided between O-ring seals. This allows connection to a leak detection system to be used as an indicator of primary seal failure

Compatible with all Guided Wave analyzers and many other analyzer brands

Safety Features of the Flow Cell

As a patented (US Pat #5,452,082) safety feature, each sapphire window is double O-ring sealed. A passage from between the O-rings is brought to a common port terminated in a ½” Class 300 flange. It is highly recommended that a sensor sensitive to the process material be attached to this port with its alarm set at an appropriate level.

Catalogs

Related Searches

- LAR Process Analysers gas analyzer

- LAR Process Analysers concentration analyzer

- LAR Process Analysers monitoring analyzer

- LAR Process Analysers liquids analyzer

- LAR Process Analysers benchtop analyzer

- LAR Process Analysers automatic analyzer

- LAR Process Analysers solids analyzer

- Spectrometer

- LAR Process Analysers process analyzer

- Portable analyser

- LAR Process Analysers continuous analyzer

- LAR Process Analysers integration analyzer

- LAR Process Analysers water analyzer

- LAR Process Analysers real-time analyzer

- LAR Process Analysers oxygen analyzer

- LAR Process Analysers compact analyzer

- LAR Process Analysers laboratory analyzer

- LAR Process Analysers infrared analyzer

- LAR Process Analysers calibration analyzer

- LAR Process Analysers in-line analyzer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.