- Metrology - Laboratory

- Analytical Instrumentation

- Process flow cell

- Process Insights

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

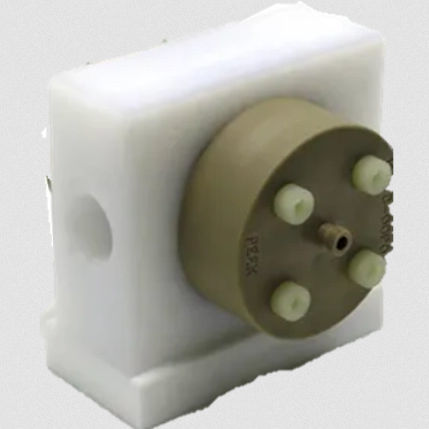

Process flow cell GUIDED WAVE™ Teflon®

Add to favorites

Compare this product

Characteristics

- Other characteristics

- process, Teflon®

Description

Our GUIDED WAVE™ Teflon Process Flow Cell was developed for sample streams that are either extremely corrosive or intolerant to metal contamination. None of the cell’s wetted parts are constructed of metal. Only smooth Teflon and sapphire surfaces contact the process stream. Otherwise, the Teflon Process Flow Cell utilizes the same optical components as our popular Multi-Purpose Metal Flow Cell. Corrosion resistant stainless steel is used in the outer cell construction to maintain a rigid, stable optical path length. Hence, it has the same high optical efficiency. Plus, it is guaranteed not to leak! The GUIDED WAVE PFA/PEEK Flow Cell was developed for environments that must be completely metal-free.

Teflon not only “cold flows” but has a very large temperature coefficient of expansion. To maintain the all-important pathlength, stainless steel rods are embedded in the Teflon body. The windows and other precision optics are held rigidly in place by these rods. Thus, preventing even the slightest change to the critical pathlength during the normal expansion and contraction that naturally occurs with Teflon products. The measurement accuracy of the stream is therefore never compromised due to this or any other phenomena. If necessary, the cell can be completely disassembled for inspection or deep cleaning. The reassemble step is easily accomplished without changing the critical pathlength. For your convenience, the Teflon Flow Cell is equipped with a clean-out port that provides access to the windows for cleaning without disconnecting fibers or plumbing.

Catalogs

Related Searches

- LAR Process Analysers gas analyzer

- LAR Process Analysers concentration analyzer

- LAR Process Analysers monitoring analyzer

- LAR Process Analysers liquids analyzer

- LAR Process Analysers benchtop analyzer

- LAR Process Analysers automatic analyzer

- LAR Process Analysers solids analyzer

- Spectrometer

- LAR Process Analysers process analyzer

- Portable analyser

- LAR Process Analysers continuous analyzer

- LAR Process Analysers integration analyzer

- LAR Process Analysers water analyzer

- LAR Process Analysers real-time analyzer

- LAR Process Analysers oxygen analyzer

- LAR Process Analysers compact analyzer

- LAR Process Analysers laboratory analyzer

- LAR Process Analysers infrared analyzer

- LAR Process Analysers calibration analyzer

- LAR Process Analysers in-line analyzer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.