- Products

- Catalogs

- News & Trends

- Exhibitions

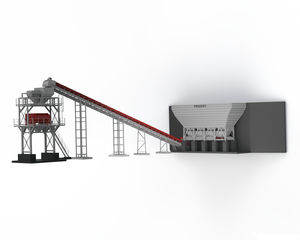

Electric concrete mixer PROMIXfixedautomatictwin-shaft

Add to favorites

Compare this product

Characteristics

- Motor type

- electric

- Mobility

- fixed

- Other characteristics

- automatic, twin-shaft

- Capacity

1 m³, 2 m³, 3 m³

(35.3 ft³, 70.6 ft³, 105.9 ft³)Min.: 1 m³

(35.3 ft³)Max.: 4 m³

(141.3 ft³)

Description

The body is produced with a welded joint in a high-strength structure with its design and material quality.

In the interior where the mixing takes place, the entire body surface is covered with wear-resistant replaceable linings. In this way, it has a very long working life.

Minimum Time

It is very important to complete the ready mixed concrete production as soon as possible. The full contact of cement and aggregate with each other ensures that the concrete has high strength and the expected quality is achieved.

Mixing

The mixing process is carried out by two shafts rotating in opposite directions on which the arms and pallets are mounted.

Thanks to the shafts rotating in the opposite direction, the arms and pallets allow the materials required for concrete to be mixed homogeneously in the shortest time.

The arrangement of the arms and pallets connected to the twin shafts is in opposite directions as well as the rotation directions. In this way, there is no area that the pallets do not scan in the internal volume of the mixer.

Automatic Lubrication

Mixer bearings need to be properly lubricated to keep them operating longer in harsh conditions. Therefore, there is an automatic lubrication system mounted on the mixer body.

The automatic lubrication system undertakes the lubrication of the bearings at certain intervals.

Hydraulic Unloading

Mikser çıkış kapağı hidrolik pistona bağlıdır. Bu hidrolik piston da bir güç ünitesiyle tahrik edilmektedir. Otomasyon sistemine akuple edilerek, boşaltma kapağının istenilen zamanda, tam açılma ve tam kapanma sağlanır.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.