- Products

- Catalogs

- News & Trends

- Exhibitions

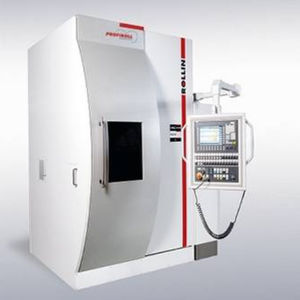

Spline rolling machine PB 200CNC

Add to favorites

Compare this product

Characteristics

- Type

- spline

- Other characteristics

- CNC

- Rolling force

3 kN

- Part diameter

93 mm, 142 mm, 150 mm

(4 in, 6 in, 6 in)

Description

The PB 200 is a modern Rolling system for burnishing of annulus gears with internal and external gear. The innovative machine design includes usage of 3 pieces Burnishing Dies as well as workpiece jig. This three-jaw jig as main spindle allows a specific control of revolutions including reverse rolling. The whole system is controlled by a Profiroll Control with touchscreen based on Siemens S7-1500. Besides small required floor space the integrated automation concept including orientation station is ensuring a convenient and easy connection to standard automation systems.

The burnishing process includes many advantages: The load ratio of surface (Rmr) is increased due to smoothened surface. This includes not only a higher wear resistance and fatigue endurance limit but also lower noise emissions as well as a higher usable tool lifetime of previous machining operation.

Features of PB 200:

compact machine design

integrated orientation station

excellent accessibility

eRolling DMC Station

no coolant lubrication needed

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.