- Products

- Catalogs

- News & Trends

- Exhibitions

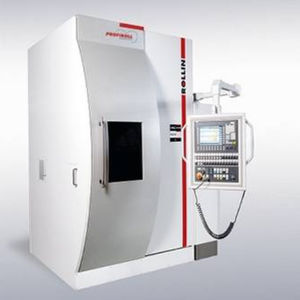

Spline rolling machine PRI 120 /ACCNC

Add to favorites

Compare this product

Characteristics

- Type

- spline

- Other characteristics

- CNC

- Part diameter

60 mm, 120 mm

(2 in, 5 in)

Description

Process chain center sleeve. Special kinematics in the PRI 120 CNC/AC® developed by Profiroll allow to roll back tapers into already hobbed or shaped internal splines. Cycle times of 15-20s are usual values and an already connected handling allows highest process safety.

The machine base is built as ribbed, warp resistant body and has low vibration due to the cast execution of machine bed. Through the implementation of modern proportional valve and driving technique in conjunction with the PROFIROLL CNC control, a direct influence on the rolling process is possible. The accurate and repeat positioning of the rolling slide is guar- anteed by the backlash free roller guide ways. The control system of fers variety of possible rolling, service and diagnosis programs. The innovative workpiece handling system makes in conjunction with the rolling process the shortest cycle time possible.

Features:

special drive chain

Graphical user interface

Process visualization

Data management

User guidance

Integrated workpiece handling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.