Hammer mill D serieshorizontalfor rubberfor wood

Add to favorites

Compare this product

Characteristics

- Technology

- hammer

- Orientation

- horizontal

- Product applications

- for rubber, for wood

Description

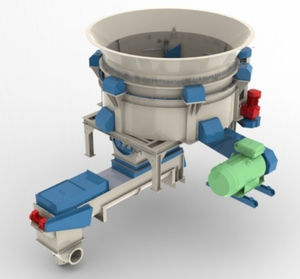

The PROMILL STOLZ desintegrators are designed to reduce difficult products having an irregular sizing and with a high percentage of sticky, fatty or very moist materials.

That machines are polyvalent and reliable. They are thus usefull in a lot of industries.

Technical specifications of that 4 series of desintegrator are :

Their extremely sturdy design of the meccano type where all the components are interchangeable,

Gravitary feeding by the top of the desintegrator

Extra thick side flanges made of cast iron for the DA series and steel for the other series. The DC series is in addition equipped with interchangeable wear plates,

The crushing chamber fitted with an impact plate with counter-hammers,

The rotor of the "standard" type in the DA version, the rotor is systematically "heavy" in the other versions,

The rotor is provided with hardened hammers and is assembled on a high diameter shaft disposed on bearings built-in flanges.

Pneumatic extraction of the product is done on the rear side of the hammermill. Handling of the product can be done by a conveyor belt, a chain conveyor or an archimedian screw.

The drive is achieved by means of one or two motors coupled in-line on the rotor shaft,

The crusher unit and its motors are supported by anti-vibratory rubber feet.

Catalogs

No catalogs are available for this product.

See all of Promill Stolz‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.