Hammer mill ROTOMILLSverticalgrain

Add to favorites

Compare this product

Characteristics

- Technology

- hammer

- Orientation

- vertical

- Product applications

- grain

Description

They can likewise be used for the reduction of stalks or haulms, as also the coarse splitting of cereals.

The bales to be crushed are generally fed in by means of a portable conveyor, a fork or bucket loader, without having to previously remove the binder. The crushed product is cleared away by screw, chain or belt conveyor with, if necessary, decompression.

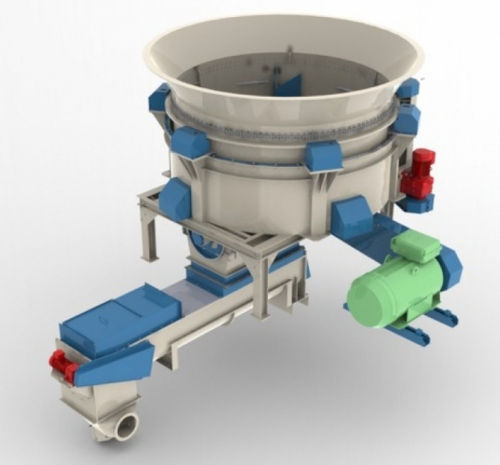

They are made up of the following standard units :

A general support frame with feet and fixed circular bowl at the top,

A heavy rotor fitted with hammers and supported by two high capacity bearings,

A rotor drive assembly made up of pulley belts and electric motor,

An electric motor support plate with transmission belt tensioning device,

An interchangeable crushing grille mounted under the rotor enabling the desired grain size of the finished product to be achieved. The standard ROTOMILL model is supplied with 3 grids according to your choice,

A circular reception hopper for the bales to be crushed, held vertically and laterally by rollers mounted on bearings. A drive chain is fastened to the circumference of this hopper,

A drive device for the circular reception hopper made up of a reduction gear-variator motor and a transmission system using a shaft and chain pinions,

A PROMILL STOLZ control and regulation cabinet type "STOPMILL" acting by stop/go pulses on the reception bowl drive, in relation to the amperage of the main motor.

Catalogs

Rotomill

4 Pages

Rotomill straw crusher

4 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.