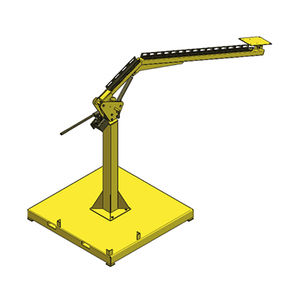

MIG welding machine WA 1000 / WA 1500buttMAGautomatic

Add to favorites

Compare this product

Characteristics

- Technique

- MIG, butt, MAG

- Operational mode

- automatic

- Applications

- for metal

- Other characteristics

- hydraulic, longitudinal, gantry

Description

Automatic longitudinal welding with joint tracking system for structural beams types H, I, T, L, HKS, HSQ and tapered. It includes mechanical automated seam tracking system and is suitable for SAW / GMAW welding process. WA 1000 / WA 1500 allows to program the welding sequence and welding parameters in automatic cycle.

Key features

Primary features and benefits:

Automatic fillet and butt welding with joint tracking

Multipass welding

One-man operation

Reduction of costly over-welding and decrease of filler metal usage

User friendly interface – multiple languages

Accepts most of welding MIG-MAG power sources

Automatic longitudinal top quality MIG-MAG welding of long structural Box beams and H, I, T, HKS, HSQ. Single or multi-pass automatic fillet/butt welding with mechanical-electro joint tracking system. Minimized welding defect&reduced non-productive time and it’s One-man operation!

Beam rotator & positioner as well as H-beam hydraulic assembly work-station for fitting and tacking are available as option.

Technical specification

GWS type WA 1000 and WA 1500

Length of track / welding13m / 12m

16m/15m

19m/18m

Upon request 19m+

Max workpiece height WA 1000 / WA 15001m (39.4”) / 1.5m (60”)

Max welding speedUp to 1 m/min solid wire

Possibility to implement additional functionality

e.g. welding length, intermittent weldsYES

Welding power sources

up to 90kg (198 lbs)/eachYES

Possibility of changing welding parameters

during welding process “on the flyOption

Fume extraction system (recommended)Recommended option for operator safety

VIDEO

Catalogs

Related Searches

- Welding system

- Automatic welding system

- Welder

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Butt welding machine

- Hydraulic welding machine

- MIG welding system

- High-precision welding system

- Programmable welding system

- Welding carriage

- MAG welding system

- Custom welding system

- Automated welding carriage

- Vertical welding system

- Longitudinal welding machine

- Arc welding carriage

- Thermal sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.