MIG welding carriage RAIL BULLMAGautomatichorizontal

Add to favorites

Compare this product

Characteristics

- Technique

- MIG, MAG

- Operating mode

- automatic, horizontal, vertical, continuous

- Other characteristics

- magnetic

Description

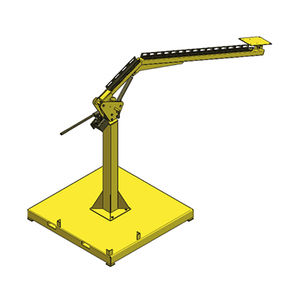

RAIL BULL is a track carriage designed for plate bevelling or establishing groove and fillet welds with or without oscillation using MIG/MAG welding torches. The machine can work in PA (flat), PB (horizontal vertical), PC (horizontal), PD, PE (overhead), PF (vertical up) and PG (vertical down) welding positions.

Key features

Rail Bull | Welding & Cutting Track Carriage

Rail Bull moves along either rigid or semi-flexible track on both ferromagnetic and non-ferromagnetic materials thanks to rack and pinion drive and tracks fixed to flat or curved surfaces by means of various magnetic or vacuum units. The minimum curvature radius required for semi-flexible track is 5 m (16 ft).

Applications

Trailer manufacturing

Truck tanks

Oil tanks

Water storage tanks

Pressure vessels

Vessel overlay/Hard facing

Bridge girders

Structural steel

Structural towers

Panel welding

Transformers

Shipyards

Any application demanding long, continuous welds

Primary features and benefits:

Compact, lightweight design with durable aluminum cast housing

Convenient Power Supply 115–230 V, 50–60 Hz or

42 V, 50–60 Hz

Quick clamping torch holder mechanism for different types of MIG/MAG torches with diameters of 16–22 mm (0.63–0.87”); up to 35 mm (1.38”) option

Precise torch adjustment with screw drive cross slide

Ready to work in both vertical and horizontal positions

Multifunctional LED display (process parameters & warnings)

Consistent heat input reduces distortion

Reduce wasted filler metal – eliminates over welding

Automatic arc on/off initiates welding and travel, simultaneously

Closed loop position control system based on electrical motor with encoder, ensures

VIDEO

Catalogs

Related Searches

- Welding system

- Automatic welding system

- Welder

- Metal welding system

- Arc welding system

- Precision welding system

- Manual welding system

- Butt welding machine

- Hydraulic welding machine

- MIG welding system

- High-precision welding system

- Programmable welding system

- Welding carriage

- MAG welding system

- Custom welding system

- Automated welding carriage

- Vertical welding system

- Longitudinal welding machine

- Arc welding carriage

- Thermal sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.