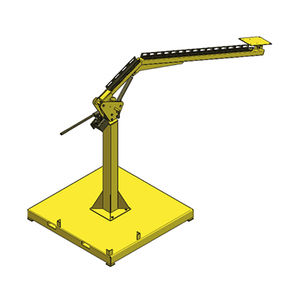

Arc welding machine RAIL BULL 2thermalmanualprogrammable

Add to favorites

Compare this product

Characteristics

- Technique

- arc, thermal

- Operational mode

- manual

- Other characteristics

- programmable, vacuum, custom

- Power

120 W

Description

Automated welding and cutting tractor – Rail Bull 2 can be custom configured for a variety of welding, thermal cutting and gouging applications on flat or curved plate, tube and pipe. It’s suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials. Rail bull 2 is best choice for your cutting and welding automation process.

Primary features and benefits:

Fully modular mechanized travel carriage can be custom configured for a variety of welding, thermal cutting and gouging applications on flat or curved plate, tube and pipe

Linear torch oscillator to produce weave welds

Active compensation of torch position vertically and horizontally by means of modular automatic seam tracking system

Programmable path of stitch welds

Limit switch stops the arc and travels the tractor to the initial position

Minimum curvature radius required is 5 m (16 ft) for the semi-flexible track

With ring tracks diameters from 200 mm OD up to 3000 mm OD are allowed

Ergonomic remote control pendant with simple and easy to find control knobs makes adjustments possible without lifting of the operators welding hood

Magnetic adhesion of the pendant provides firm grip on ferromagnetic materials

Suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials thanks to rack and pinion drive and various tracks equipped with magnetic or vacuum units

Rail Bull 2 produces consistent high quality welds and cuts in a fraction of the time required by manual operations

High speed up to 3 m/min makes plasma cutting available

make sure you check our other automated welding and cutting tractors

VIDEO

Catalogs

Related Searches

- Welding system

- Automatic welding system

- Welder

- Metal welding system

- Arc welding system

- Precision welding system

- Manual welding system

- Butt welding machine

- Hydraulic welding machine

- MIG welding system

- High-precision welding system

- Programmable welding system

- Welding carriage

- MAG welding system

- Custom welding system

- Automated welding carriage

- Vertical welding system

- Longitudinal welding machine

- Arc welding carriage

- Thermal sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.