Arc welding carriage Rail Tugautomaticcontinuous

Add to favorites

Compare this product

Characteristics

- Technique

- arc

- Operating mode

- automatic, continuous

Description

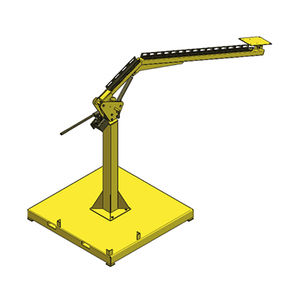

The Rail Tug is a digitally controlled tractor designed for the mechanization of welding and thermal cutting processes. Featuring a rack and pinion drive system with electronic speed control, the Rail Tug creates weld bead geometry which is exact to your specifications, reducing costly over welding and decreasing filler metal usage.

Key features

Rail Tug | Welding and Cutting Tractor

The Rail Tug can be used with semi-flexible track for plate and tank work with a minimum radius of 5 m (16 ft) or adapted to bent ring rail for pipe and tube applications. Standard ring rails are available for tube diameters from 200 mm (8”) up to 3000 mm (10 ft), whereas custom rolled tracks can be used for tube diameters between 3 m (10 ft) and 10 m (32 ft). Using a vacuum system allows the track to be clamped to non-ferrous surfaces (stainless steel, aluminum etc.) The Rail Tug economically meets a broad array of welding and cutting applications on flat or curved plate, tube and pipe.

Applications

Trailer manufacturing

Truck tanks

Oil tanks

Water storage tanks

Pressure vessels

Bridge girders

Structural steel

Structural towers

Panel welding

Transformers

Shipyards

Any application demanding long continuous welds

Primary features and benefits:

Compact, lightweight design

Closed-loop speed control system based on electric motor with encoder – ensures increased accuracy of speed

Rack and pinion drive

Consistent heat input reduces distortion

Reduces wasted filler metal – eliminates over welding

Digital LED display for presetting of travel speed

Automatic arc on/off initiates welding and travel simultaneously

VIDEO

Catalogs

PRODUCTS AT A GLANCE

6 Pages

Related Searches

- Welding system

- Automatic welding system

- Welder

- Metal welding system

- Arc welding system

- Precision welding system

- Manual welding system

- Butt welding machine

- Hydraulic welding machine

- MIG welding system

- High-precision welding system

- Programmable welding system

- Welding carriage

- MAG welding system

- Custom welding system

- Automated welding carriage

- Vertical welding system

- Longitudinal welding machine

- Arc welding carriage

- Thermal sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.