Seam welding system GWSverticalgantryhigh-precision

Add to favorites

Compare this product

Characteristics

- Other characteristics

- seam, vertical, gantry, high-precision

Description

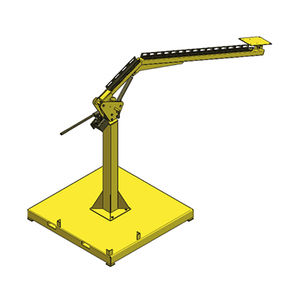

Gantry Welding System is intended for longitudinal welding of long structural beams with web in vertical position and with active compensation of working positions of torches. It can be integrated with MIG/MAG or SAW welding equipment according to particular customer’s needs.

The standard version comprises 5 numerically controlled axes, controlled by a computer system with TFT graphic display. Active compensation of position of both torches with regard to the welding seam enables precision of 0,1 mm. The system comprises a high-precision maintenance-free, planetary gearbox and all axes are powered by high-class servo motors controlled by a digital inverter. High-precision linear guides ensure precise and smooth motion of all system axes. The torch holders are fitted on machine’s supports through anti-collision joints. It’s rigid and heavy duty construction is based on aluminum section profiles.

Main Features

GWS is controlled by digital controller

The system comprises a high-precision maintenance-free, planetary gearbox

All axes are powered by high-class servo motors

Every servo motor is controlled by a digital inverter

High-precision linear guides ensure precise and smooth motion of all system axes

The torch holders are fitted on machine’s supports through anti-collision joints

Rigid and heavy duty construction is based on aluminium section profiles

GWS is equipped with active safety systems enable protection of the staff

System software can be customized to the customer’s welding technology

Depending on a type of welding equipment there is a possibility of registration of welding parameters like current and voltage in a function of time

VIDEO

Catalogs

Related Searches

- Welding system

- Automatic welding system

- Welder

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Butt welding machine

- Hydraulic welding machine

- MIG welding system

- High-precision welding system

- Programmable welding system

- Welding carriage

- MAG welding system

- Custom welding system

- Automated welding carriage

- Vertical welding system

- Longitudinal welding machine

- Arc welding carriage

- Thermal sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.