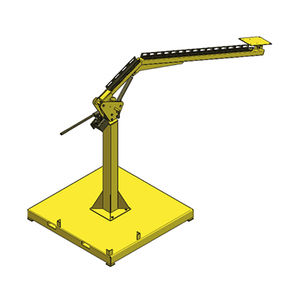

Safety rail VTSsteelstainless steel

Add to favorites

Compare this product

Characteristics

- Type

- safety

- Material

- steel, stainless steel

Description

Promotech’s vacuum track system provides firm grip of track segments on materials such as stainless steel, aluminium, carbon steel, etc… Light-weight and modular design enables easy adjustment and fitting of the system to specific needs depending on welding or cutting applications and working positions (e.g. flat, horizontal or vertical). System is compatible with standard Rail Bull track segments.

Main features and benefits:

back up reservoir for added safety in case of a power failure; back up vacuum offers additional time to safely secure a welding tractor and tracks; it also greatly reduces installation time of the whole system

maximum plate temperature up to +320°C (608°F)

only 100 mm (4”) minimal distance from heat source to vacuum pads

Back up reservoir for added safety in case of a power failure

The reservoir offers additional time to safely secure a welding tractor and tracks

Only 100 mm ( 4″) min. distance from heat source to vacuum pads

Maximum plate temperature up to

+ 320 C (608 F)

Modular design can easily configure the whole Vacuum Track System depending on your needs and job in hands. A large selection of system elements including rigid and semi-flexible rails, vacuum pads, hoses, valves and fittings help you make your work even more efficient. By means of Vacuum Track System you can perform lots of welding and cutting tasks in horizontal and vertical positions on both ferrous and non-ferrous materials.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Promotech‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.