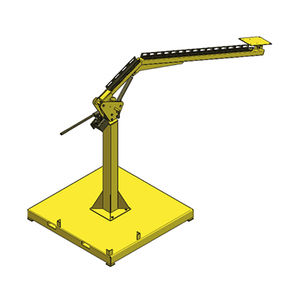

Automatic welding carriage LIZARD

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

Description

LIZARD is a portable, programmable welding carriage designed to produce consistently high quality welds (both continous and stitch). Welding patterns and parameters include weld length, distance between welds, reverse fill, crater fill time. Optional oscillation attachment enables production of weave welds.

Key features

Lizard | Programmable Welding Carriage

The unit enables weld bead geometry that is exact to the required specifications, substantially reducing costly over welding and decreasing filler metal usage. LIZARD can be programmed in continuous or stitch welding modes. Welder friendly two function buttons enable programming of selected welding patterns and parameters such as weld length, distance between welds, reverse fill, crater fill time and others. LIZARD travels at full speed between stitches, which saves valuable welding time. A very important optional feature of LIZARD is oscillation attachment to produce weave welds. The unit can identify its connection automatically and configure suitable operating modes. Torch oscillator increases significantly functionality of Lizard welding carriage by allowing it to operate in most out-ofposition welding jobs.

The newest improved guide arms family makes a proper welding tractor positioning even easier.

7 different guide types are dedicated to various welding applications and positions

include a number of fixing grooves for your convenience

enable simpler, easier and more consistent adjustment of how guide arms stick out

secure proper tilting of the carriage into a direction of its movement

maintain a permanent contact with the workpiece

allow either interval or continuous guide arms adjustment

VIDEO

Catalogs

Related Searches

- Welding system

- Automatic welding system

- Welder

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Butt welding machine

- Hydraulic welding machine

- MIG welding system

- High-precision welding system

- Programmable welding system

- Welding carriage

- MAG welding system

- Custom welding system

- Automated welding carriage

- Vertical welding system

- Longitudinal welding machine

- Arc welding carriage

- Thermal sealer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.