- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Inflatable shutter for watertightness testsrubberdouble

Add to favorites

Compare this product

Characteristics

- Type

- inflatable

- Applications

- for watertightness tests

- Material

- rubber

- Other characteristics

- double

Description

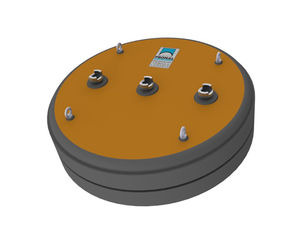

Pronal has designed an inflatable stopper system for implementing hydraulic tests on superheater dryer units (GSS). This system is a combination of two solutions:

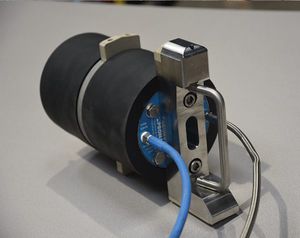

An inflatable stopper which plugs the outlet on the side of the VISM valve (OHP),

And on the other side, an inflatable jack mounted on a metal support is inserted into the outlet of the GSS grille. This solution can be completely dismantled.

This removable system is installed via a manhole with a 400 mm diameter. The test pressure reaches around 25.5 bar. Testing is validated on-site by a certifying company. This inflatable pipe plug is mostly used on nuclear sites.

The GSS hydraulic testing serves to certify the strength and tightness of the GSS grille. This Pronal inflatable stopper system reduces outage time by avoiding cutting/welding pipework that could also include the fitting of welded caps.

Detailed information

Material:

Cylinder ring in NPVC

SBR (Styrene Butadiene Rubber) for the OHP2

Technique: hot vulcanisation in a vacuum autoclave

Dimensions:

Dia. 1150 mm for the cylinder

Dia. 920 mm for the stopper

Form: cylindrical

Inflation: by water

Max. inflation pressure:

38 bar for the inflatable seal

35 bar for the stopper

Catalogs

No catalogs are available for this product.

See all of PRONAL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.