- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

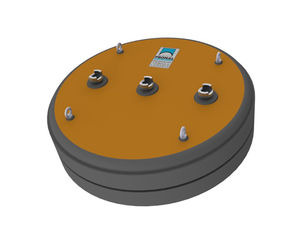

Inflatable shutter for watertightness testsrubber

Add to favorites

Compare this product

Characteristics

- Type

- inflatable

- Applications

- for watertightness tests

- Material

- rubber

Description

The primary circuits in nuclear power plants are equipped with swing type check valves. The ASN has determined the frequency that the tightness of these swing valves must be tested.

This is why Pronal has developed a range of “tailor-made” inflatable stoppers for testing Bouvier Darling valves on the primary circuits.

As a result, this range of stoppers is used to test the tightness of the swing mechanism on the sealing surfaces. As an example, the inflatable stoppers for testing Bouvier Darling valves are installed on the RIS / RCP circuit.

In contrast to the pneumatic stopper for testing – VELAN RATEAU, the stoppers for testing “Bouvier Darling” valves are inflatable. They are equipped with a system of inflatable seals composed of layers of PMUC rubber and an inter-seal for verifying the tightness of the stopper. This system is equipped with a mechanical stop which ensures that the stopper is held in place in the main body of the valve.

It is these stoppers which equip the METEOR® test bench. This test bench is used to measure the tightness of valves at a constant pressure. It can provide both instantaneous and averaged measurements of any leakage flow. Hydraulic testing is performed at a pressure of 10 Bar.

Detailed information

Materiel: NBR (Nitrile Butadiene Rubber) PMUC

Technique: hot vulcanisation in a vacuum autoclave

Dimensions: DN80 / DN150 / DN250 / DN300

Form: cylindrical

Inflation: by water

Temperature resistance: -25/+85°C

Max. inflation pressure: 17 Bar

Catalogs

No catalogs are available for this product.

See all of PRONAL‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.