- Metrology - Laboratory

- Analytical Instrumentation

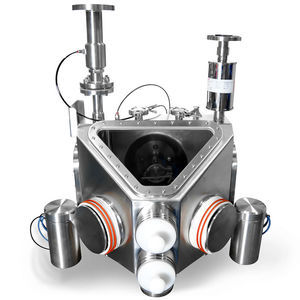

- Powder sampler

- ProSys Sampling Systems Limited

Screw sampler powderautomaticmanual piston

Add to favorites

Compare this product

Characteristics

- Sample type

- powder

- Technology

- automatic, screw, manual piston

Description

Screw Auger Sampler

• Extracts a representative powder sample from pack-off booths, drop chutes and hoppers.

• Can be either manually or automatically operated.

Operation

• The auger is run in reverse to clean the sampler of any powder.

• The auger is then run in a forward direction, this pushes the powder towards the sample outlet.

• When the sample reaches the sample outlet it falls by gravity into the sample bottle.

• The auger is run in reverse to ensure that any powder residue is removed from the sampler prior to shutting down.

Features

• All contact parts are 316L s.s. or Hastelloy® C22 with PTFE or Kalrez® Elastomers.

• PTFE Stuffing Box for manual sampler

• Borosilicate sample bottle with ISO GL 45 connection

• Finish: Internal Polish 0.25Ra, External Polish 0.5Ra

Options

• Manually or automatically controlled.

• A Quick Disconnect Sampler allows the operator to remove the screw between batch runs or at regular intervals for cleaning.

• Containment of the sample bottle using a cabinet/glovebox.

• Sample bottle connection can be machined to suit customer supplied bottle.

• Nitrogen Purge/Solvent Flush Valve can be fitted.

Catalogs

No catalogs are available for this product.

See all of ProSys Sampling Systems Limited‘s catalogsOther ProSys Sampling Systems Limited products

Powder/ Solids Sampling

Related Searches

- Automatic sampling system

- Liquid sampling system

- Powder sampler

- Compact sampling system

- Water sampler

- Solids sampler

- Air sampler

- Wastewater sampler

- Viscous product sampler

- Vacuum sampling system

- In-line sampling system

- Sludge sampler

- Slurry sampler

- Manual piston sampler

- Screw sampling system

- Fixed-volume sampler

- Sampling station

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.