- Production Machines

- Plastics Processing

- ProTec Polymer Processing

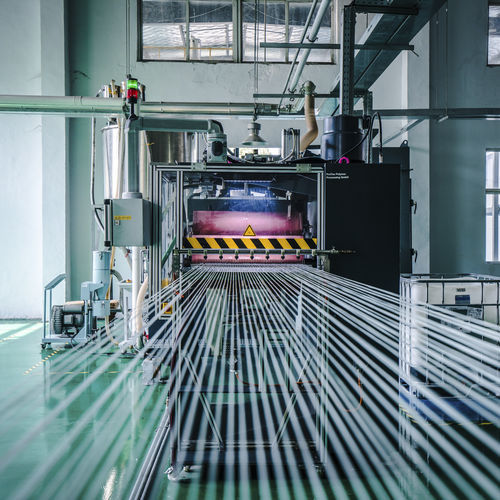

Profile pultrusion line LFTfor long fiber reinforced thermoplastics

Add to favorites

Compare this product

Characteristics

- Type

- profile

- Treated material

- for long fiber reinforced thermoplastics

Description

LFT pellets produced with ProTec production lines utilize best-in-class technology, resulting in superior material performance. We develop LFT-Pultrusion solutions that meet the latest technical challenges and your customers demanding requirements.

We design and build Pultrusion lines that enable you to manufacture LFT pellets with wide range of polymer matrices and different fiber strengths. The Pultrusion process optimally coats the fiber strand in the impregnation tool for the production of LFT pellets for the manufacture of high strength and low weight plastic parts. The advantages of LFT are becoming widely recognized, particularly in the automotive parts industry, and significant new applications are expected to develop in the packaging, appliances, sports equipment and facilities, medical and aerospace components.

VIDEO

Catalogs

LFT-Pultrusion Lines

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.