- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

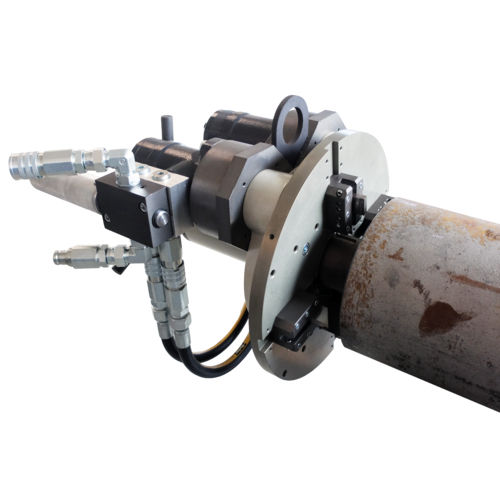

Electric chamfering machine US80pneumatichydraulichand-held

Add to favorites

Compare this product

Characteristics

- Operation

- electric, pneumatic, hydraulic

- Type

- hand-held

- Applications

- weld preparation, for tubes, precision, for weld seam preparation

- Other characteristics

- squaring, semi-automatic

- Chamfer width

Max.: 16 in

Min.: 3.1 in

- Chamfer angle

Max.: 45 °

Min.: 30 °

Description

The US80 portable tube and pipe heavy duty beveler combines durability, reliability, efficiency and versatility in one machine, providing a safe and easy use for all operators. The standard

tool-plate will accept multiple tool bits, allowing up to four simultaneous machining operations. Such operations may include 30°, 37°30, 45° bevels with or without land, J-bevels, compound bevels, facing, counterboring operations, etc.

The US80 heavy duty beveler will perform repeatable high quality weld preparations on all types of materials including mild steel, chrome, stainless steel, duplex, super duplex, copper-nickel alloy steel, inconel, P91, aluminium, copper and exotic alloys. It can be either pneumatically, electrically or hydraulically driven. The tool bits can be changed and adjusted very quickly. Carbide tool inserts may also be used.

• Transportable

• Powerful Machining Equipment

• Easy and Safe use for the Operators

• No Heat Affected Zone

• High Accuracy

• Fast and easy mounting

• The tool bits can be changed and adjusted very quickly

• Adapted for works in tight spaces

• The machine can be used in all positions: vertical, horizontal, over head

• Versatile Cutting Head: the tool-holder plate can accept up to 4 tool bits for simultaneous machining operations (land, bevel, counterboring, j prep)

• Smooth and Burr-Free Surface Finish

• No vibration during the machining process

Standard Capacity: 80mm - 355mm (3.149“ - 13.976“)

Extended Capacity: 80mm - 406.4mm (3.149“ - 16“)

Cold machining - No heat affected area - Repetitive quality - Ergonomics - Reliability - Operator safety

VIDEO

Catalogs

Related Searches

- Cutting system

- Metal cutting system

- Cutting machine for industrial applications

- Knife cutting system

- High-precision cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- Metal fabrication cutting system

- Beveling machine

- High-performance cutting system

- Rotary blade cut-off machine

- Steel cutting system

- Carbon steel cutting machine

- Electric beveling machine

- Portable beveling machine

- Pipe beveling machine

- Heavy-duty cutting system

- Beveling cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.