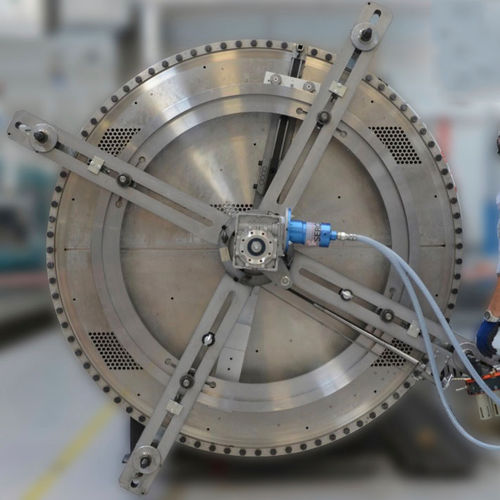

SERCO XP-Series

Portable Facing Units

The SERCO XP machining units are designed for the repair and maintenance of virtually all dimensions and materials of many diverse components such as:

Flanges

Grooves

Safety valves

Sealing surfaces

Hole surfaces

High pressure valves

Flat seats

Conical seats

Manholes

RTJ Grooves

Used in many diverse and demanding industries:

Power Plant (Nuclear, Thermal, Hydraulic)

Refineries

Petrochemical

Chemical

Pharmaceutical

Food and Beverage Industry

Shipbuilding

Valve manufacturing / machining

Maintenance and Repair contractors operating in the field

High precision, High performance

Enhanced efficiency

Light weight

Perfect for use in tight areas

Operating principle

The Serco XP machines all work on the same principle. They are set up and fixed in place by a column/arm system. This clamping principle allows high precision performance of internal machining operations.

The XP machine setup is fast and easy. The design allows for independent adjustment of the concentricity and parallelism to reach a precision of 1/100 mm with a surface finish of 1.6 Ra.