- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

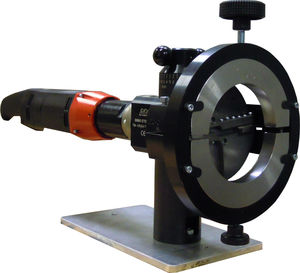

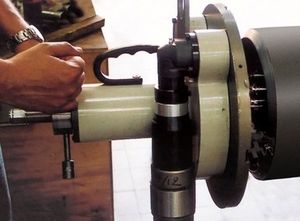

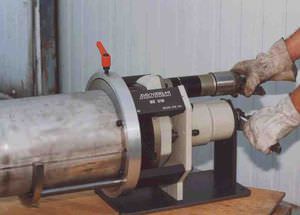

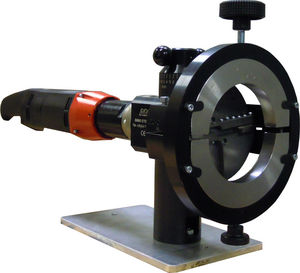

Electric chamfering machine MF170portablesheet metalwith automatic feeder

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Type

- portable

- Applications

- sheet metal

- Other characteristics

- with automatic feeder

Description

Electrically driven product requires three phase 380 V supply. The product has a machining and clamping range of 60, 3 mm to 168 mm and it comes with an OD feed of 60 mm and 10 to 80 rpm of rotation. It weighs around 180 kg. For bevelling the maximum wall thickness required is C-steel of 8 mm and stainless steel of 7 mm. The product has vital technical features; robustly designed machine is completely electrically driven. It is versatile and flexible and assures ease of use and adjustment. The machine comes with a huge capacity and can be used for varied purpose. It boasts a ratchet spanner along with a concentric clamping. Machine is equipped with oversize motor reducer and a mechanical variator that aids in regulating speed of the rotation easily and quickly. Protection housing ensures for long service life, the machine also comprises automatic clutch advances. System comb efficiently tears off chips. Carbide inserts or Tools HSS. The MF-series machine type is exclusively designed to cut and bevel pipes and tubes ranging from approximately 60.3 mm OD – 168 mm OD in a single operation. 37.5° and 30° are possible bevel angles. The MF170 machine works well with carbide inserts.

VIDEO

Catalogs

Related Searches

- Cutting system

- Metal cutting system

- Cutting machine for industrial applications

- Knife cutting system

- High-precision cutting system

- Tube cut-off machine

- Precision cutting system

- Aluminum cutting system

- SS cutting machine

- Metal fabrication cutting system

- Beveling machine

- High-performance cutting system

- Rotary blade cut-off machine

- Steel cutting system

- Carbon steel cutting machine

- Electric beveling machine

- Portable beveling machine

- Pipe beveling machine

- Heavy-duty cutting system

- Beveling cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.