- Metrology - Laboratory

- Inspection and Monitoring

- Vibrating monitoring system

- PRÜFTECHNIK Alignment Systems GmbH

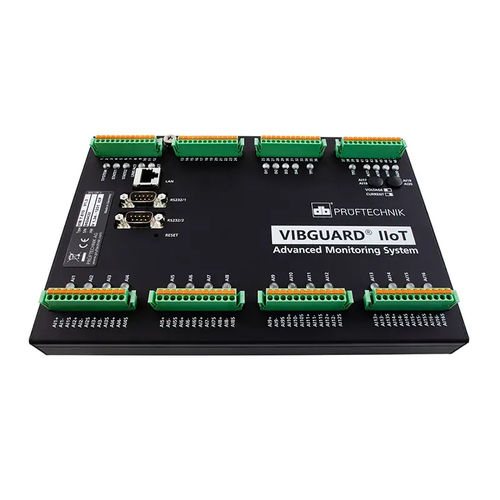

Condition monitoring system VIBGUARD IIoTvibrationmeasurementprocess

Add to favorites

Compare this product

Characteristics

- Type

- condition, vibration

- Applications

- measurement, process, for machines, diagnostic, for predictive maintenance

- Other characteristics

- online, multi-channel

Description

Online condition monitoring of machine parks

• 12, 16 or 20 analogue channels for vibration monitoring and signal processing

• Time signal, characteristic value, FFT spectrum, kinetic wave path (orbits), torque

• Smart and easy IIoT solution for predictive maintenance

• Advanced alarm handling tools are available for monitoring specific machine failures

• Full access to data visualization portal with OMNITREND Asset View software subscription

• Flexible installation (DIN rail, etc.)

Product description

VIBGUARD IIoT offers a choice of 12, 16 or 20 measuring channels which are sampled in parallel and synchronously. This allows even the most complex equipment to be continuously monitored and protected against unplanned shutdowns.

VIBGUARD IIoT works autonomously and performs the measurement tasks automatically. The measurement data such as time signal, characteristic value, FFT spectrum, kinetic wave path (orbits), or torque are processed in parallel and almost in real time and can be correlated with the running production process. The fast data processing makes VIBGUARD IIoT the perfect monitoring and diagnostic system for systems with short operating cycles, such as cranes, machine tools, presses, or for machines with highly dynamic processes, such as test benches, wind turbines or chain conveyors. All critical fans and pumps can also be monitored easily but effectively with VIBGUARD IIoT.

VIBGUARD IIoT measures time signals, overall values, FFT spectra, shock pulse, orbits and much more on either 12, 16 or 20 parallel channels for almost all kind of signal inputs.

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRÜFTECHNIK Alignment Systems GmbH‘s catalogsOther PRÜFTECHNIK Alignment Systems GmbH products

Online Condition Monitoring

Related Searches

- Measurement monitoring device

- Continuous monitoring device

- Condition monitoring device

- Process monitoring device

- Online monitoring device

- Benchtop monitoring system

- Vibration monitoring system

- Machine monitoring device

- Compact monitoring device

- Smart monitoring device

- Multi-channel monitoring device

- Diagnostic monitoring device

- Predictive maintenance monitoring device

- Pump monitoring device

- Compressor monitoring system

- 6-channel monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.