- Metrology - Laboratory

- Inspection and Monitoring

- Vibrating monitoring system

- PRÜFTECHNIK Alignment Systems GmbH

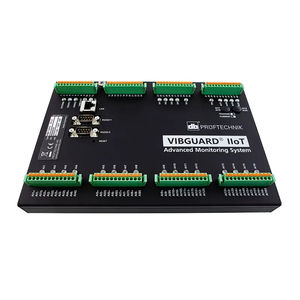

Condition monitoring system VIBGUARD compact vibrationdiagnosticfor pump

Add to favorites

Compare this product

Characteristics

- Type

- condition, vibration

- Applications

- diagnostic, for pump, for compressors

- Configuration

- compact

- Other characteristics

- continuous, smart, 6-channel

Description

Condition Monitoring of highly dynamic critical assets

• Ideal for extruders, centrifuges, turbocompressors, vacuum pumps, and more

• Smart and easy IIoT solution for predictive maintenance

• Wi-Fi hub available

• Characteristic value trend storage with adjustable data reduction and Intelligent Event Recording

• Access to free browser-based OMNITREND Asset View software

• Individual installation solutions including IP65 housing

• Free software updates

VIBGUARD compact for individual assets

VIBGUARD compact offers six measuring channels for continuous monitoring. It is perfectly suited for fast and highly dynamic equipment. In particular, the VIBGUARD compact meets the requirements of critical assets that are characterized by high availability, high aggregate values, complex drives and changing operating conditions.

Whether pre-installed in an IP65 compact housing or as a switch cabinet system module, the VIBGUARD compact is perfect for diagnostic condition monitoring of individual extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges.

All six measuring channels are designed as highly dynamic analog input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables. They provide in depth diagnostic data such as time signals or envelope signals, and up to 6 characteristic values such as vibration characteristic or bearing condition.

The 'Intelligent Event Recorder' stores relevant results, fully automatically and continuously, providing the basis for comprehensive machine diagnostics.

VIDEO

Catalogs

No catalogs are available for this product.

See all of PRÜFTECHNIK Alignment Systems GmbH‘s catalogsOther PRÜFTECHNIK Alignment Systems GmbH products

Online Condition Monitoring

Related Searches

- Measurement monitoring device

- Continuous monitoring device

- Condition monitoring device

- Process monitoring device

- Online monitoring device

- Benchtop monitoring system

- Vibration monitoring system

- Machine monitoring device

- Compact monitoring device

- Smart monitoring device

- Multi-channel monitoring device

- Diagnostic monitoring device

- Predictive maintenance monitoring device

- Pump monitoring device

- Compressor monitoring system

- 6-channel monitoring system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.