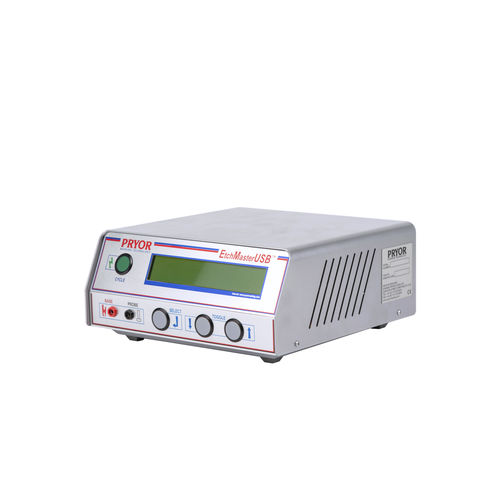

The Etchmaster USB is an Electrochemical Etching station that uses an electric current to create identification, 2D barcodes and logo designs without distorting the work piece. The Electrochemical Etching station is often used in small to medium production of aerospace components where tight tolerances over surface treatment exist.

• Portable chemical etching system

• Uses an electric current to create a mark

• Able to create alphanumeric identification, Data Matrix codes and logo designs

• Often used for small to medium production of aerospace components

• Ideal where tight tolerances over surface treatments exist

• Often used in aerospace applications

The Etchmaster USB is an Electrochemical Etching station that uses an electric current to create identification, 2D barcodes and logo designs without distorting the work piece.

Pryor’s Electrochemical Etching station is a very quick and easy to use etching system that creates a mark using an electric current. Controlled by PC software, the system is fully programmable and capable of creating many different mark designs, including alphanumeric data, Data Matrix codes and logos. The output voltage and waveform are completely selectable, allowing the user to tailor the output to the material being marked. This enables high contrast, high quality marks to be created on virtually all electro-conductive materials, regardless of surface hardness. The machine is even capable of creating white marks as desired for certain applications.

The Electrochemical Etching station is fully portable and can be supplied with a portable workbench for ease of storage that houses a lockable cabinet to secure the PC.