- Industrial machines and equipment

- Printing, Marking and Engraving

- Dot peen marking machine

- Pryor Marking Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

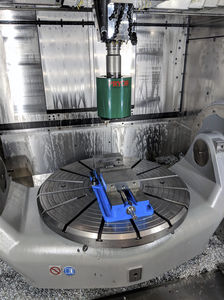

Electromagnetic marking machine BenchDot 150-150dot peenmetalaluminum

Add to favorites

Compare this product

Characteristics

- Technique

- electromagnetic, dot peen

- Material

- metal, aluminum

- Configuration

- benchtop

- Applications

- data matrix, for flat and cylindrical objects

- Other characteristics

- stainless steel, compact, programmable, high-definition, with touch screen, traceability, with identification, 2D data matrix

- X travel

Max.: 150 mm

(5.91 in)150 mm

(5.91 in)Min.: 0 mm

(0 in)- Y travel

Max.: 150 mm

(5.91 in)150 mm

(5.91 in)Min.: 0 mm

(0 in)

Description

Pryor BenchDot 150-150 is a bench mounted dot-peen marking (also known as impression marking or dot marking) machine with programmable touch-screen controller. These are robust and compact marking devices that can easily integrate into a workshop environment due to their quality build and compact size.

- Suitable for marking small to medium sized components of unusual shapes and dimensions

- Ideal for marking alphanumeric identification and Data Matrix codes

- Available with a wide range of accessories to tailor to your specific marking requirements

- Machine of choice for rigorous specifications of dot matrix marking in the aerospace industry

- A single marking system for all requirements

he user can easily change the font, the size of the mark, the shape of the mark (straight, angled, arc, reverse), the depth of the mark, the density of the ‘dots’ and each final design can be saved as a set ‘layout’. This makes it very easy for an operator to save multiple layouts for different components which can then be selected as the part is loaded, providing fast and accurate setup every time.

Marking Window Area 150mm x 150mm

Machine Head Cover 398mm (W) x 446mm (D)

Machine weight – minimum 40kg

Controller weight - 6.5kg

Electrical supply - 220v 50Hz, 110v 60Hz

Max stylus to base distance - 415mm (using 50mm stylus)

Standard column length gives 375mm clearance between the bottom of the solenoid and the base table.

X, Y axis control - Steppermotor driven

Work piece hardness - Max. 62 HRC (800HV)

Character sizes - 0.15mm – 99.9mm in 0.15mm increments

Memory capacity: up to 1350 inscription layouts

VIDEO

Catalogs

BenchDot

3 Pages

Related Searches

- Marking machine

- Laser marking workstation

- Metal marking workstation

- Benchtop marking workstation

- Plastic marking workstation

- High-speed marking machine

- Industrial marking workstation

- Automated marking machine

- Compact marking workstation

- Laser engraving system

- Aluminum marking workstation

- Dot peen marking machine

- Integration marking machine

- Hand-held marking machine

- Air-cooled marking machine

- Industrial engraving system

- Pneumatic marking machine

- Marking and engraving system

- Laser marking and engraving system

- Marking system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.