Coil unwinder AutoUnwindpaperfilmautomatic

Add to favorites

Compare this product

Characteristics

- Type

- coil, paper, film

- Operation

- automatic

- Roll diameter

Max.: 12 in

Min.: 3 in

Description

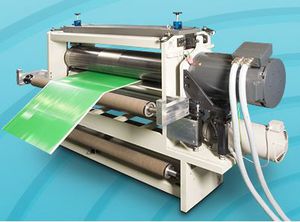

The fully automatic unwinder is used to continuously supply materials to a production line.

It is used in the following production lines: Coating, printing or thermal calendering as well as any type of finishing process where a constant production speed is required.

The advantages of the AutoUnwind series are the possible roll mounting and splice systems for the various requirements. The mother roll can be picked up with a clamping shaft or “without a shaft” using clamping heads. The web connection with a so-called splice can be carried out with adhesive tape, thermal welding or also with ultrasonic welding.

In addition, it is possible to carry out both the introduction of the mother roll and the discharge of the empty core automatically by using a transport carriage. Optionally, the material can also be trimmed.

Catalogs

No catalogs are available for this product.

See all of PSA‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.