- Packing - Handling - Logistics

- Conveying

- Automatic feeding system

- PSM International

Automatic feeding system

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

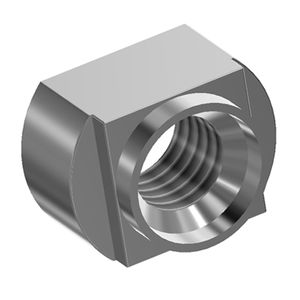

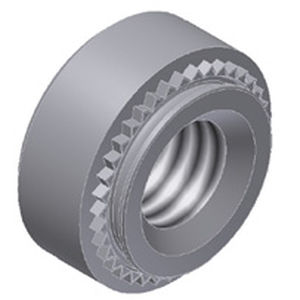

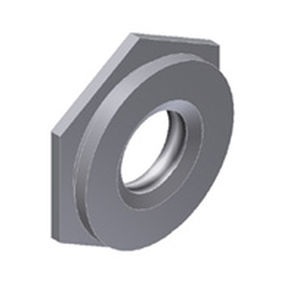

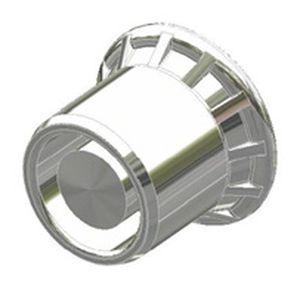

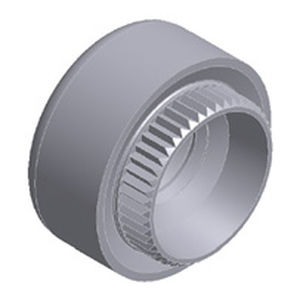

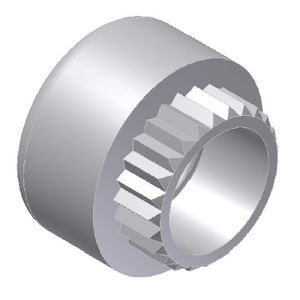

Feed Systems for in-die sheet metal fasteners offer considerable cost savings. A variety of options and system designs are available utilizing existing press equipment, from manual loading through to fully automated handling and installation. The feed systems can be used in a progression or transfer press, robotic cell or off-line presses, feeding both nuts and studs in multiple orientations.

Advantages :

• Used in transfer, progression, off-line presses and within robotic cells; increasing output and cost saving.

• Feeding orientation can be “top down”, "bottom up" or cammed in from the side.

• Improved efficiency.

• PSM designs and manufactures the system to ensure the fastener is controlled thoughout the entire process.

• Increased productivity with feed rates up to 60 strokes per minute.

• Foreign objects are prevented from entering the feed head.

• Quick release mechanisms for timely disconnect.

• Constant monitoring and control of the fasteners.

• Built in full proofing to minimize rejections.

• Installation accuracy and easier assembly of mating parts.

• Commissioning & servicing packages available.

Catalogs

No catalogs are available for this product.

See all of PSM International‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.