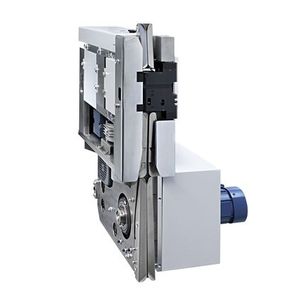

Steel strap strapping head VS32 L

Add to favorites

Compare this product

Characteristics

- Strap type

- for steel straps

Description

When it comes to heavy-duty strapping applications and meeting the highest demands in every respect, the VS32-L heads from TITAN are the right choice. They feel at home in heavy industry when strapping coils, tubes and profiles.

Thanks to their robust construction and technology, they work extremely reliably in these areas. And fast: A transport speed of 1.7 m per second allows strapping of even very large objects in a flash.

Speaking of “in no time”: The proven pneumatics of the VS32-L heads generate a tensioning force of up to 20,000 N using air pressure. This enormous clamping force requires high joining strength with the help of two welding spots produced without contact using the patented TITANARG® TIG welding process.

With the VS32-L-R product variant, strapping planar packages with a contact surface of 150 mm and circular packages from 700 mm is possible thanks to a smaller base plate. For the VS32-L heads, TITAN can guarantee excellent availability to meet the high demand.

Because heavy industry is often about being there fast.

• Technical Data :

• Kind of drive : Electro pneumatic

• Tension force : 4,000 - 20,000 N (adjustable)

• Mains voltage : 400 V AC / 50 Hz

• Control voltage : 24 V

• Welding voltage

• (TITANARG®) : 400 V ; 460 V

• Strap conveying speed : ca. 1.7 m/s

• approx. 5.6 ft/s

• Dimensions : 680 x 580 x 750 mm (L x W x H)

• 26.8 x 22.8 x 29.5" (L x W x H)

• Weight : 200 kg

• 440.9 lb

• Air pressure : min. 5 bar flow pressure

• max. 6 bar

• Air consumption

• (depending on channel size) : approx. 0.2 - 0.3 m³ per strapping

• approx. 7.1 - 10.6 ft³ per strapping

• Cross-section : 1/2"

Catalogs

metal

8 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.