- Packing - Handling - Logistics

- Packing and Packaging

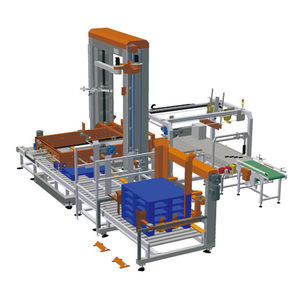

- Robotic palletizer

- Qingdao Ausense Packing Equipment Co., Ltd.

Robotic palletizer SMD12for cardboard boxes

Add to favorites

Compare this product

Characteristics

- Type

- robotic

- Product applications

- for cardboard boxes

Description

* Use touch screen operation to realize fully automatic, which can display production speed, cause of failure and location.

* Servo motor and axis structure, full servo control, adjustment is simple and fast.

* Single column type palletizing, small footprint and easy maintenance. .

* High degree of automation as the PLC can ordering stacking number, pallet supply and discharge

* Delta monitors and motion controllers are used for easy and convenient operation.

* The safety door and cover are equipped with electrical induction devices. When the cover door is opened and the machine stops working, the personnel can be protected.

* Stacking is stable and efficient, which can save labor.

The robotic arm palletizing machine consists of a lifting and lowering Z-axis, a translational X-axis and a gripper to form the main system of the full servo palletizing machine. At the same time, it is combined with a palletizing machine, a palletizing area conveying line and a feeding conveying line to form a set of palletizing system. The palletizing machine puts the cartons on the pallet in a certain arrangement, carries out automatic stacking, stacks multiple layers, and then pushes it out, so that the forklift truck can be transported to the warehouse for storage. This equipment adopts PLC+ touch screen control to realize intelligent operation management, which is simple and easy to master. It can greatly reduce labor cost and labor intensity.

Model: SMD12

Efficiency: 4-6 times/min

Voltage: 220V 50Hz 3Phase

Power: 9kw

Air supply: 4-7kg/m3

Frame material: Sprayed carbon steel

Control system: Delta PLC

Screen: Delta

Electrical parts: Schneider

Sensor: Sick

VIDEO

Catalogs

No catalogs are available for this product.

See all of Qingdao Ausense Packing Equipment Co., Ltd.‘s catalogsOther Qingdao Ausense Packing Equipment Co., Ltd. products

Others

Related Searches

- Packing machine

- Automatic packing machine

- Wrapping machine

- Bagging machine

- Automatic labelling machine

- Automatic wrapping machine

- Packing machine for the food industry

- FFS bagging machine

- Stretch film wrapping machine

- Strapping machine

- Pallet wrapping machine

- Palletizer

- Automatic strapping machine

- Bagging machine for the food industry

- Vacuum packing machine

- Shrink wrapper

- Film packing machine

- Automatic sleeve wrapping machine

- Turntable wrapping machine

- Bell type packing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.