- Packing - Handling - Logistics

- Conveying

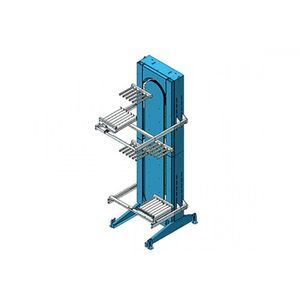

- Roller conveyor

- Qingdao Ausense Packing Equipment Co., Ltd.

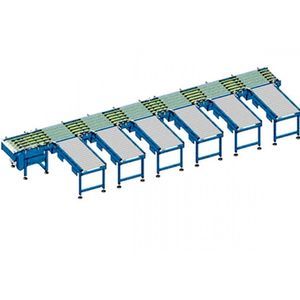

Roller conveyor horizontaltransportmodular

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Form

- horizontal

- Function

- transport

- Construction

- modular

- Drive mechanism

- electric drive

- Transported product

- bearing

- Maximum load

1,500 kg

(3,306.934 lb)- Speed

12 m/min, 16 m/min, 18 m/min

Description

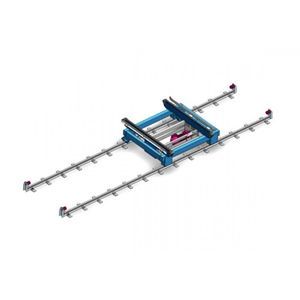

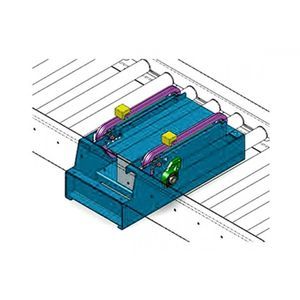

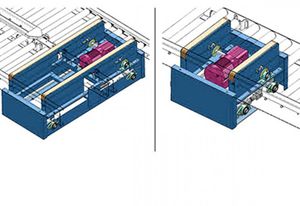

Slewing mechanism: the slewing mechanism adopted in this design adopts gear type slewing bearing, which has the advantages of simple structure, high slewing accuracy, large anti-axial radial force and smooth operation. The gear type rotary bearing is placed in the middle of the bottom frame, the outer ring of the gear type rotary bearing is fixedly connected with the upper roller table machine, and the inner ring is fixedly connected with the bottom frame. The gear type rotary bearing outer ring is driven by a reduction motor mounted on the gear.

Load shifting mechanism: adopt double chain roller table machine, the specific structure is the same as the foregoing.

Accessory device: photoelectric support (detection of rotation deceleration position, accurate in place detection).

Purchased parts configuration: reducer motor SEW, chain with hangzhou donghua.

Surface coating: steel wire brush, sand paper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m.

Φ89×3mm

Double-sprocket roller (10A-13Z)

Φ76×3mm/Φ89×3mm

Side guide on roller

Side profile 125×70×15×5mm

External gear rotary support turntable bearings

Motor mounting inside

Catalogs

No catalogs are available for this product.

See all of Qingdao Ausense Packing Equipment Co., Ltd.‘s catalogsOther Qingdao Ausense Packing Equipment Co., Ltd. products

Conveyor

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Electric drive conveyor

- Sorting machine

- Drag chain conveyor

- Inclined conveyor

- Modular conveyor

- Automatic sorting machine

- Pallet rail conveyor

- Discharge conveyor

- Transfer rail conveyor

- Curved rail conveyor

- Carton conveyor

- Automatic conveyor

- Rail transfer car

- Vertical rail conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.