- Products

- Transfer unit

- Qingdao Ausense Packing Equipment Co., Ltd.

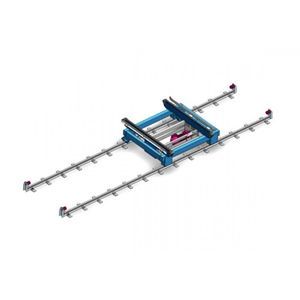

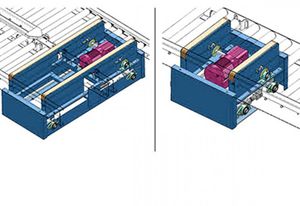

Transfer unit

Add to favorites

Compare this product

Description

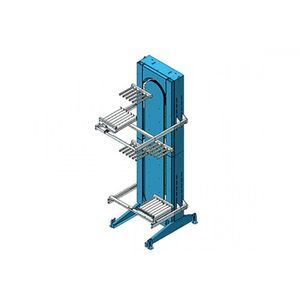

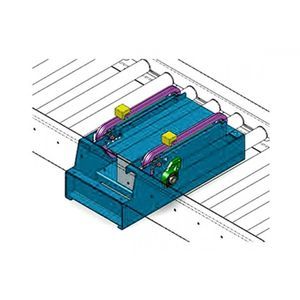

Jacking mechanism: welding type bottom frame with height adjusting foot, base type deceleration motor is placed in the middle of the bottom frame, two shafts are connected by bearing pedestal and bottom frame on both sides respectively, two shafts are connected with the motor by driving chain respectively. Each shaft and both ends are equipped with needle roller bearing crank arm to form the jacking structure.

Load shifting mechanism: adopt double chain roller table machine, the specific structure is the same as the foregoing.

Accessory device: photoelectric support (lift two positions, in place detection).

Purchased parts configuration: reducer motor SEW, chain for hangzhou donghua, bearing with seat TR, ha shaft for bearing.

Surface coating: steel wire brush, sand paper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m.

• Double-sprocket roller (10A-13Z)

• Φ76×3mm/Φ89×3mm

• Side guide on roller

• Side profile 125×70×15×5mm

• R series gear motor

• Lift height 70mm

Catalogs

No catalogs are available for this product.

See all of Qingdao Ausense Packing Equipment Co., Ltd.‘s catalogsOther Qingdao Ausense Packing Equipment Co., Ltd. products

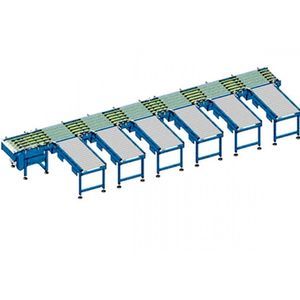

Conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.