- Packing - Handling - Logistics

- Handling and Lifting

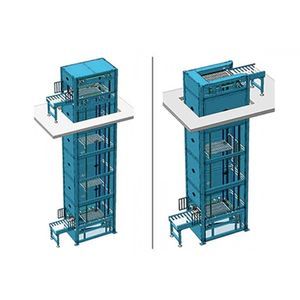

- Pallet lift

- Qingdao Ausense Packing Equipment Co., Ltd.

Tilting pallet lift

Add to favorites

Compare this product

Characteristics

- Options

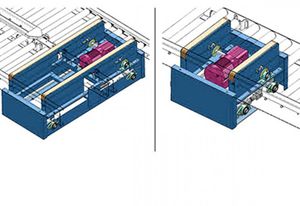

- tilting

Description

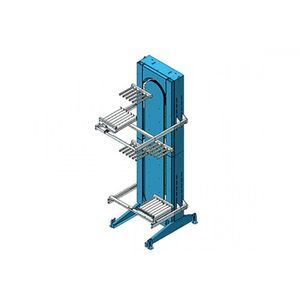

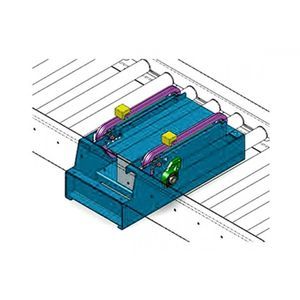

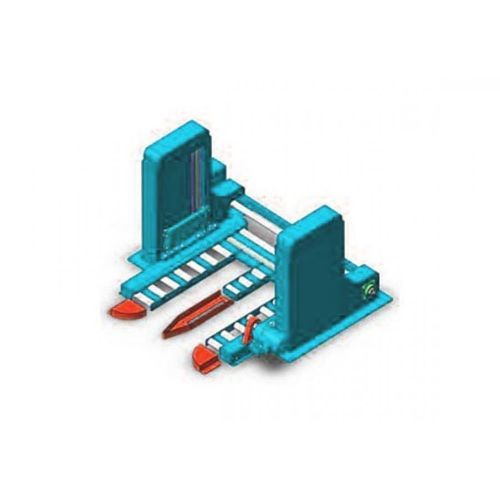

Lifting mechanism: there are four lifting chains hanging at the four corners of the loading platform. The two sides of the loading platform are guided by regulating wheels, and the lifting is stable. Effectively prevent the cargo from overturning due to overweight or in the process of operation.

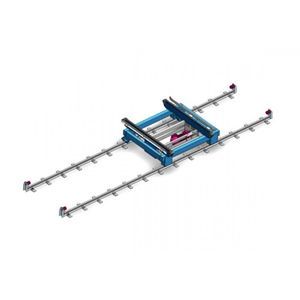

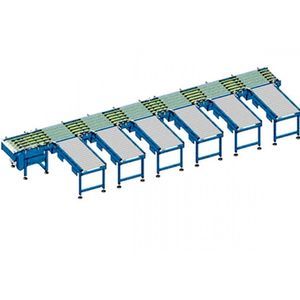

Loading table: three-row roller table machine; The diameter of the roller is 60mm, and the minimum conveying surface can be reduced to 80mm from the ground. The equipment can be used with hydraulic forklift, electric forklift and internal combustion forklift.

External parts configuration: reducer motor SEW? Hangzhou donghua for chains TR for bearings with seat and ha shaft for bearings.

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m.

• Double chain roller (08 b - 14 z) Φ 60 x 2 mm

• Double-sided plate guide

• Frame steel 125×70×5mm

• Drum spacing 152.4mm

• R series side mounted motor

• Chain lifting, minimum height 80mm

• Can be directly docked cattle

Catalogs

No catalogs are available for this product.

See all of Qingdao Ausense Packing Equipment Co., Ltd.‘s catalogsOther Qingdao Ausense Packing Equipment Co., Ltd. products

Conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.