- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Qingdao Ausense Packing Equipment Co., Ltd.

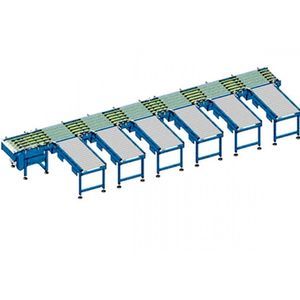

Belt conveyor curvedelectric driveprofile

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- curved

- Drive mechanism

- electric drive

- Transported product

- profile

- Speed

Max.: 100 m/min

Min.: 20 m/min

Description

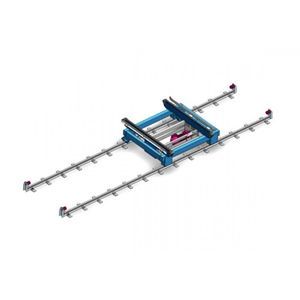

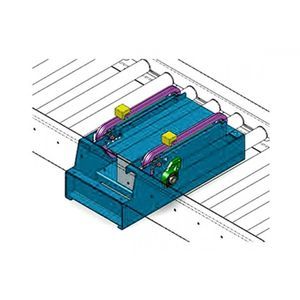

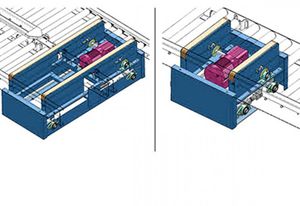

The curved belt conveyor is driven by the side bending chain chain in the conical roller sprocket to drive the turning belt to complete the material turning transportation.

One. main mechanical structure and features:

Turning belt: adopt the special turning belt for self-mold opening.

Chain: adopt 10B-SB side bent chain.

Body: adopt 4mm steel plate to be formed by welding after cold bending.

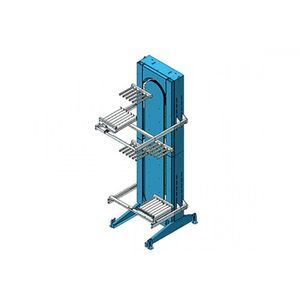

Supporting leg: it adopts customized profile welding type, which has the advantages of firmness and good stability. Connect the frame with the connecting plate with bolts, adjust the connection between the foot base and the ground, and adjust the height of the conveying surface 50mm, as shown in the following figure:

Drive device: motor, chain drive.

Surface coating: steel wire brush and sandpaper are used to remove rust on the frame, support legs, guide parts, accessories and other parts, and the grease is removed by acid washing. After phosphating, the surface is sprayed with epoxy powder and baked. Spraying color shall be specified by party a's color card.

External parts configuration: the motor should be SEW, belt should be wynn, bearing base should be TR, bearing should be ha shaft.

Catalogs

No catalogs are available for this product.

See all of Qingdao Ausense Packing Equipment Co., Ltd.‘s catalogsOther Qingdao Ausense Packing Equipment Co., Ltd. products

Conveyor

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Electric drive conveyor

- Sorting machine

- Inclined conveyor

- Drag chain conveyor

- Modular conveyor

- Automatic sorting machine

- Pallet rail conveyor

- Transfer rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Carton conveyor

- Automatic conveyor

- Rail transfer car

- Vertical rail conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.