- Packing - Handling - Logistics

- Conveying

- Roller conveyor

- Qingdao Ausense Packing Equipment Co., Ltd.

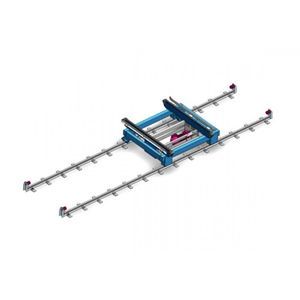

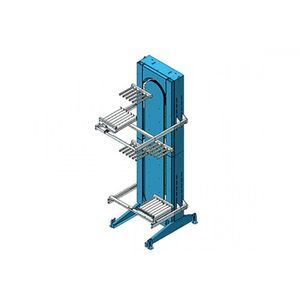

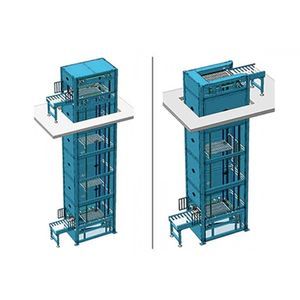

Roller conveyor horizontalstraightlifting

Add to favorites

Compare this product

Characteristics

- Technology

- roller

- Form

- horizontal, straight

- Function

- lifting, transfer

- Transported product

- carton, bag

Description

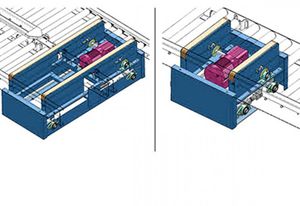

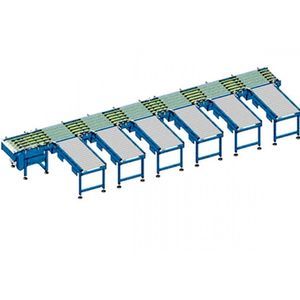

Block transfer machine used to roller machine of bag change 90 ° direction transfer equipment. When the goods are transported to the loader, the sensor detects that the goods are in place, the loader pushes the block to move, and pushes the goods to the adjacent conveyor. After the goods are sent out, the loader pushes the block to stop running.

One. main mechanical structure and features:

Push block mechanism: nylon push block installed on the chain is used as shifting transmission. The driving force is driven by a small internal motor.

Load shifting location detection: diffuse reflection photoelectric switch is used for location detection of nylon push block.

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m. Spraying color shall be specified by party a's color card.

Catalogs

No catalogs are available for this product.

See all of Qingdao Ausense Packing Equipment Co., Ltd.‘s catalogsOther Qingdao Ausense Packing Equipment Co., Ltd. products

Conveyor

Related Searches

- Rail conveyor

- Belt conveyor

- Transport conveyor

- Horizontal conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Electric drive conveyor

- Sorting machine

- Inclined conveyor

- Drag chain conveyor

- Modular conveyor

- Automatic sorting machine

- Pallet rail conveyor

- Transfer conveyor

- Unloading conveyor

- Curved rail conveyor

- Carton conveyor

- Automatic conveyor

- Rail transfer car

- Vertical conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.