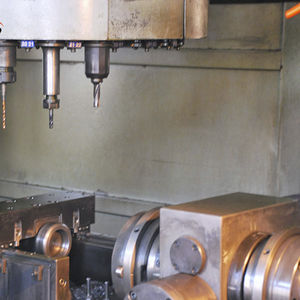

- Production Machines

- Other Manufacturing Equipment

- Steel sand casting

- Qingdao Chifine Machinery Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Cast-iron sand casting steelautomotivefor railway

Add to favorites

Compare this product

Characteristics

- Material

- cast-iron, steel

- Applications

- automotive, for railway, for the maritime sector, for the construction industry, agriculture

- Production method

- small series, medium series, large series

Description

What’s sand casting?

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 60% of all metal castings are produced via sand casting process.

There are six steps in this process:

1. Place a pattern in sand to create a mold.

2. Incorporate the pattern and sand in a gating system.

3. Remove the pattern.

4. Fill the mold cavity with molten metal.

5. Allow the metal to cool.

6. Break away the sand mold and remove the casting.

Automatic casting line

• Material: Grey iron(GG20-GG35);Ductile iron(GGG40-GGG60);

Malleable cast-iron(GTS35-10/45-06/55-04/65-02,CTW35-04/05/06/07).

• Product Size: 0-1000mm.

• Weight: 0.2kg-100kg

Other Qingdao Chifine Machinery Co., Ltd. products

Production Capability

Related Searches

- Die casting

- Investment casting

- Aluminum die casting

- Automotive die casting

- Stainless steel investment casting

- Sand casting

- Small series investment casting

- Automotive investment casting

- Medium series sand casting

- Steel investment casting

- Small series die casting

- Small series sand casting

- Zinc die casting

- Large series sand casting

- Aluminum investment casting

- Cast-iron sand casting

- Railway sand casting

- Medium series die casting

- Automotive sand casting

- Large series die casting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.