- Production Machines

- Other Manufacturing Equipment

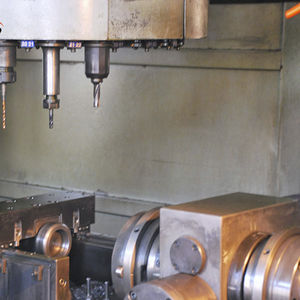

- Steel die casting

- Qingdao Chifine Machinery Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Steel die casting aluminumcopperzinc

Add to favorites

Compare this product

Characteristics

- Material

- aluminum, zinc, copper, steel

- Production method

- small series, large series, medium series

- Applications

- automotive, for the construction industry, for railway, for the maritime sector, agriculture

Description

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Advantages of die casting:

Excellent dimensional accuracy (dependent on casting material, but typically 0.1 mm for the first 2.5 cm (0.004 inch for the first inch) and 0.02 mm for each additional centimeter (0.002 inch for each additional inch).

Smooth cast surfaces (Ra 1–2.5 micrometres or 0.04–0.10 thou rms).

Thinner walls can be cast as compared to sand and permanent mold casting (approximately 0.75 mm or 0.030 in).

Inserts can be cast-in (such as threaded inserts, heating elements, and high strength bearing surfaces).

Reduces or eliminates secondary machining operations.

Rapid production rates.

Casting tensile strength as high as 415 megapascals (60 ksi).

Casting of low fluidity metals.

Other Qingdao Chifine Machinery Co., Ltd. products

Production Capability

Related Searches

- Die casting

- Investment casting

- Sand casting

- Automotive die casting

- Aluminum die casting

- Stainless steel investment casting

- Small series investment casting

- Steel investment casting

- Automotive investment casting

- Cast-iron sand casting

- Medium series sand casting

- Small series die casting

- Zinc die casting

- Aluminum investment casting

- Automotive sand casting

- Small series sand casting

- Large series sand casting

- Railway sand casting

- Steel sand casting

- Medium series die casting

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.