- Production Machines

- Cutting Machine

- Diamond wire cutting machine

- Qingdao Gaoce Technology Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

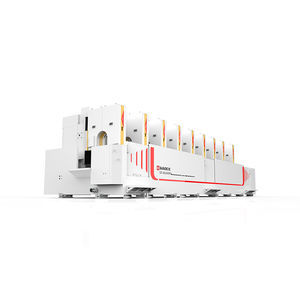

Diamond wire cutting machine GC-800XPfor monocrystalline siliconwaferfor industrial applications

Add to favorites

Compare this product

Characteristics

- Technology

- diamond wire

- Material

- for monocrystalline silicon

- Product handled

- wafer

- Applications

- for industrial applications

- Configuration

- large-format

- Cutting speed

2,400 m/min

- Overall length

6,250 mm

(246 in)- Overall width

3,400 mm

(134 in)- Height

3,200 mm

(126 in)- Weight

24,000 kg

(52,910.94 lb)

Description

With the world's first single machine dual station and adjustable wheelbase design, this equipment is playing a significant role in the slicing process of silicon wafer manufacturing. It is compatible with the cutting needs of different sizes of silicon wafers such as16X/18X/210/220/230/240, as well as the development needs of new batteries such as HJT and TOPCon for large-sized, thinned, half wafers, and rectangular wafers. Equipped with eccentric sleeve/eccentric bearing box technology, latest cutting layout, one-piece casting frame and more reliable components, this equipment can achieve a higher stability. It adopts independently developed software and tension control algorithms, reserves MES/automation interfaces, and integrates big data platform to realize intelligent production operations and fine production control. Compared to single station equipment, the footprint per GW can be reduced by 25+%, and labor cost of principal oper- ators by 30+%, which will continuously create value for clients.

Other Qingdao Gaoce Technology Co., Ltd. products

Photovoltaic Cutting Equipment

Related Searches

- GAOCE cutting machine

- Metal cutting system

- GAOCE cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- High-speed cutting system

- Sheet cutting system

- Stone cutting system

- Large-format cutting system

- Sample cutting system

- Modular cutting system

- GAOCE wire cutting machine

- Rotary cutting system

- Bar cutting system

- Roller cutting system

- GAOCE diamond wire cutting machine

- Electrical wire cutting machine

- Vertical blade cutting machine

- Kerf cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.