- Products

- Catalogs

- News & Trends

- Exhibitions

Roller conveyor shot blasting machine for metal

Add to favorites

Compare this product

Characteristics

- Type

- roller conveyor

- Applications

- for metal

Description

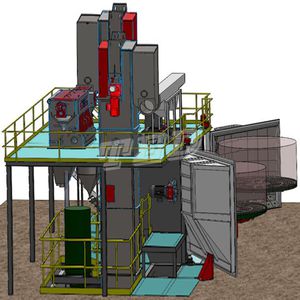

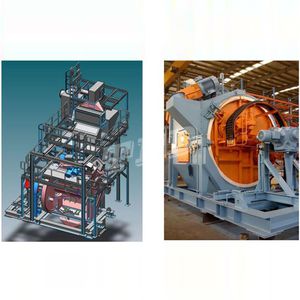

Roller conveyor machine is mainly used for processing long and (or) flat shape of the workpiece. These workpieces are continuously passed through the entering chamber, the shot blasting chamber and the cleaning chamber on a special conveyor roller table. The high efficiency shot wheel mounted on the shotcrete case can be used to handle the workpiece from each direction. The heavy duty shot wheel produced by TED The system due to the accelerated production cycle and its processing costs greatly reduced, but also to reduce the consumption of pellets, lower energy consumption.

The roller table shot blasting machine can be loaded or unloaded manually or automatically. The special shot blasting wheel arrangement make it slightly tilted in the direction of the projectile and the perfect geometric model of the shot blasting. It ensures that the workpiece will be cleaned form every surfaces by steel grit steel grit.Then the shot blasting effect of the workpiece is perfect.

Advantages:

1.The whole roller conveyor system speed is adjusted by frequency converter.The whole system not only can be operated synchronuously,but also every part can move separately.It can rotate forward and backward.

2.Rollers in blasting chamber are protected by special material jacket to prevent abrasive blasting.

Related Searches

- Blast machine

- Metal shot blasting machine

- Blast room

- Sandblaster

- Automatic blast machine

- Pressure sandblaster

- Manual sandblaster

- Manual shot blasting machine

- Continuous shot blasting machine

- Belt shot blasting machine

- Hook shot blasting machine

- Injector blast cabinet

- Automatic blast room

- Roller conveyor blast machine

- Rotating table shot blasting machine

- Compact blast machine

- Concrete shot blasting machine

- Wheel rim shot blasting machine

- Pipe shot blasting machine

- Conveyor blast room

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.