- Production Machines

- Cutting Machine

- Laser cutting machine

- Qingdao TOYO Industry Company

- Products

- Catalogs

- News & Trends

- Exhibitions

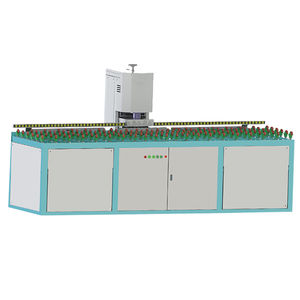

Laser cutting machine TYJT-2621for glassCNCautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for glass

- Control type

- CNC

- Other characteristics

- automatic, programmable, linear

- Cutting speed

Max.: 180,000 mm/min

(118.11 in/s)Min.: 0 mm/min

(0 in/s)- Laser power

12 W

Description

CNC Cutting Machine Series--Loading, Deliver, Cutting & Break off table – 4 in 1 Loading, Delivery & Cutting – 3 in 1 Loading & Cutting – 2 in 1

1.The sensor is from Panasonic Japan

2.German bole cutter head

3.Electrical components - Relay is American Honeywell

4.Two motor heads to drive the cutting head

5.Whole machine is free to move and 360-degree rotate

The automatic glass cutting all-in-one machine absorbs a single piece of glass through a suction cup, carries large and thick pieces of glass which is placed approximately vertically on a glass shelf, and then converts the glass to a horizontal state by mechanical transmission, and then uses a cutting system to cut it. It solves the current situation of difficult, unsafe, large cutting errors and low production efficiency which are caused by the large and thick pieces of glasses.

The machine is simple and safe to operate, features with fast, high processing accuracy and labor saving. The control system of the loading mechanism is controlled by a microcomputer (PLC programmable controller), and the cutting system adopts a CNC numerical control operating system to make the entire control system reliable, simple and high automation.

The machine can walk in the workshop and rotate 360 degrees. The machine automatically locates the angle and position of the glass, and integrates linear cutting and heterosexual cutting. From the film loading to the cutting, it is fully controlled. The equipment adopts the latest generation control system, which truly realizes the linkage between the equipment and the computer, with high accuracy and fast speed.

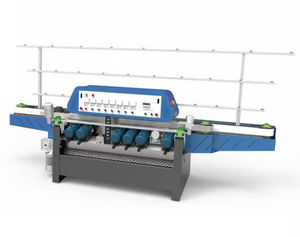

Other Qingdao TOYO Industry Company products

Glass Machinery

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.