- Products

- Quality Wire Products WLL

- Products

- Catalogs

- News & Trends

- Exhibitions

Pad

Add to favorites

Compare this product

Description

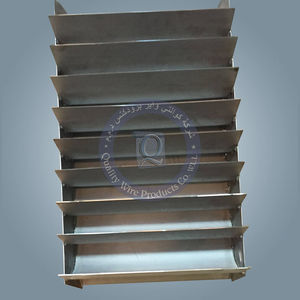

Knitted wire mesh is a set of metal wire looped and interlaced by knitting on a circular knitting machine and then corrugated to form a zig zag pattern. Several of these layers of knitted wire mesh are installed together and further reinforced or welded with grids in specific patterns according to the customer requirements.

Presently we have a production capacity which allows us to knit around 1500kgs(3300Pounds) per day and a monthly capacity of around 45,000kgs of metallic wires. With wide range of knitting width Quality wire can offer knitted wire mesh in tubular form from 100MM wide to 1800MM wide in metallic ; co knit and non metallic wires.

These knitted wire mesh can be made in different stitches by changing the needle count on the cylinders and with various needle count options available with wire diameter from 0.1MM to 0.35MM for different end use application.

We offer mesh pad with density range from 75Kg/M3 to 450Kg/M3 in metal wires and non metallic wire or co knit material.

Usage and applications

Knitted wire mesh is used as mist eliminator; insulation blanket mesh and also as filters & air bags for automotive industries.

In the refinery or oil and gas production process removal of mist or moisture from the gas is a regular process. Generally gas tends to absorb the moisture so effective removal of moisture plays a vital role in the refinery / petrochemical and desalt plants.

The mist eliminator installed inside a typical application with the zig zag pattern obstructs the flow of gas resulting in developing a friction & Due to countinous friction the moisture will form into a tiny droplet and due to gravity will fall down to the liquid.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.