- Environment - Health - Safety

- Water Treatment

- Structured packing

- Quality Wire Products WLL

- Products

- Catalogs

- News & Trends

- Exhibitions

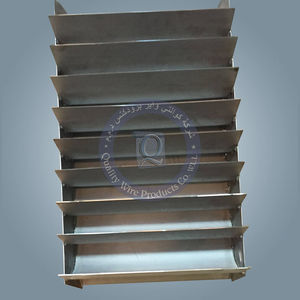

Structured packing

Add to favorites

Compare this product

Description

Structured packings usually offer less pressure drop and have higher efficiency and capacity than random packings.

The corrugated metal sheets of structured packings are arranged to create flow channels for the vapor phase.

QWP MAKE STRUCTURED PACKINGS are effectively used for separation application in the Gas Processing Plants, Chemical Processing Industries and in the Oil & Gas industries typically for separation applications.

Non-Metal Structured Packing

PVC, PP, PVDF & Teflon – Non metallic Structured Packings

Our in house process engineers design and supply various types of Structured Packing’s depending upon the requirements along with support bed and other internals according to the needs of the end user.

Metal Structured Packing

Wire Mesh Gauze Structured Packing

Sheet Metal Structured Packing in Carbon Steel, Stainless Steel and in Nickel Alloys

Types of structured packings

Metal Based Structured Packings

QWP Type 1

QWP Type 2

QWP Type 3

QWP Type 4

Plastic Based Structured Packings

QWP Type 5

Ceramic Based Structured Packings

QWP Type 6

Advantages of structured packings as compared to the use of random packing and trays

Lower pressure drop.

Higher efficiency.

Higher capacity.

Reduced liquid hold-up.

Excellent liquid spreading characteristics.

Random packings are inexpensive but efficient option to increase a tower’s capacity and/or efficiency.

The main reasons for using tower packings are:

– to reduce pressure drop throughout the column.

– to increase the contact surface.

– to reduce liquid holdup in the column.

Quality Wire offers the following packing internals which are used in the refinery and gas processing industry and mass transfer applications.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.